Introduction

Have you ever struggled to lift heavy loads safely? A snatch block can double or triple pulling force. It is essential in industrial, utility, and rescue tasks. In this article, you will learn why, how, and when to use it.

Understanding the Snatch Block

Definition and Core Components

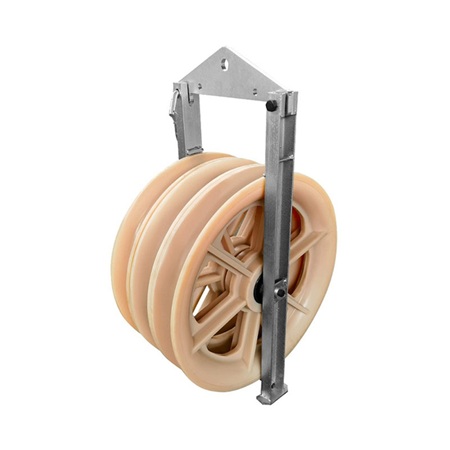

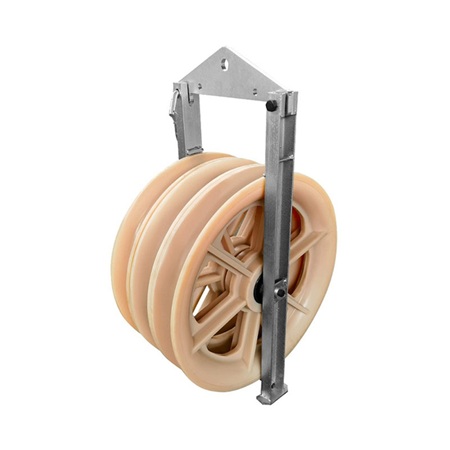

A snatch block is a heavy-duty pulley designed to handle significant loads in lifting and pulling operations. Its most distinctive feature is a hinged side plate, which allows operators to insert a rope or cable without threading it from the end, simplifying mid-line setup.

Key components include:

● Sheave (Pulley Wheel): Precision-machined to reduce friction and evenly distribute tension.

● High-Strength Casing: Protects the sheave and rope from abrasion, impact, and environmental wear.

● Attachment Fittings: Hooks, shackles, or swivels for secure connections to anchor points.

Component | Function | Benefits |

Sheave | Guides rope | Reduces friction, distributes load evenly |

Casing | Encases sheave | Increases durability and impact resistance |

Attachment | Connects to anchors | Ensures stability during lifting or pulling |

This combination ensures that a snatch block transfers mechanical force efficiently while protecting both the rope and the lifting system.

How Snatch Blocks Differ from Standard Pulleys

Snatch blocks differ from standard pulleys in functionality, flexibility, and load distribution:

● Hinged Side Plate: Allows mid-line rope insertion, unlike standard pulleys that require threading from the end.

● Load Distribution: Spreads tension across multiple points, minimizing wear on ropes and reducing stress on the lifting equipment.

● Multi-Line Pulls: Enables double or triple line pulls for heavier loads without modifying the base machinery.

Comparison Table: Snatch Block vs Standard Pulley

Feature | Snatch Block | Standard Pulley |

Rope Insertion | Mid-line insertion | End threading only |

Load Distribution | Even across multiple lines | Concentrated on single line |

Mechanical Advantage | Supports multi-line pulls | Single-line only |

Setup Flexibility | Quick adjustments | Limited flexibility |

These differences make snatch blocks more efficient and versatile for complex lifting or pulling operations.

Types of Snatch Blocks

Snatch blocks come in different designs to accommodate various operational needs:

1. Swing-Side Snatch Block

● Hinged plate swings open for easy rope insertion.

● Ideal for heavy-duty loads where rapid installation is needed.

2. Snatch Ring

● Lightweight and rotates on a soft shackle.

● Best for synthetic ropes and applications requiring reduced weight.

Considerations for Selection:

● Rope compatibility: wire rope vs synthetic cable.

● Load capacity and sheave diameter.

● Weight and portability for on-site operations.

Type | Rope Compatibility | Strength | Typical Use Case |

Swing-Side | Wire or synthetic | Heavy-duty | Construction, utility, rescue |

Snatch Ring | Synthetic only | Moderate | Lightweight lifting, marine, transport |

Choosing the right type ensures both safety and efficiency in lifting, rigging, and pulling tasks across various industries.

Key Advantages of Using a Snatch Block

Mechanical Advantage in Lifting

A snatch block can significantly increase the pulling capacity of a lifting device. By redirecting the rope back to the load or anchor, it effectively doubles or even triples the mechanical force applied by a winch or hoist. For example:

● Construction lifts: Moving steel beams to higher floors using fewer winch rotations.

● Utility pole handling: Raising heavy poles safely with reduced strain on the primary lifting equipment. This mechanical advantage allows operators to handle heavier loads than would otherwise be possible with a single line, while maintaining controlled and steady movement.

Load Distribution in Rigging

Snatch blocks distribute the force of a load across multiple lines, reducing concentrated stress on a single cable or device. Key effects include:

● Lowered tension on lever hoists and hand pullers, which minimizes wear and risk of failure.

● More balanced force distribution, which helps prevent rope slippage or abrasion against anchor points.

● Even load distribution enhances efficiency, making it possible to lift or pull with smoother motion and less energy expenditure.

Heavy Load Handling

Snatch blocks are widely used for managing heavy loads in various settings:

● Vehicle recovery: Extracting stuck vehicles from mud, sand, or snow with reduced winch strain.

● Lifting machinery: Moving industrial equipment in warehouses or construction sites.

● Cargo movement: Adjusting or transporting heavy cargo in logistics or marine environments. Technical products like JITAI Snatch Blocks provide reliable load control in these scenarios, ensuring consistent performance and stable handling during operations.

Multi-Line Pulls and Trade-Offs

Multi-line setups using snatch blocks allow operators to multiply pulling force efficiently. Common techniques include:

1. Double-line pulls: Rope runs through the snatch block and returns to the vehicle or anchor, doubling the pull force.

2. Triple-line pulls: Use two snatch blocks at separate anchors to further increase mechanical advantage. Trade-offs of multi-line pulls:

3. Line speed is reduced as the rope travels a longer path.

4. Rope length requirements are doubled or tripled.

Pull Type | Mechanical Advantage | Rope Requirement | Speed Impact |

Single-line | 1x | Standard | Full speed |

Double-line | 2x | Double length | Half speed |

Triple-line | 3x | Triple length | One-third speed |

Understanding these trade-offs is essential for planning efficient and safe lifting operations.

Safety Considerations

Safe operation of snatch blocks requires adherence to key safety practices:

● Working Load Limit (WLL) checks: Ensure the snatch block and associated gear can handle the load.

● Proper anchoring: Select stable anchors like beams, poles, or vehicles rated for the applied forces.

● Personal Protective Equipment (PPE): Gloves, helmets, and eye protection reduce risk during lifting or pulling. Correct setup of snatch blocks reduces the risk of rope failure, equipment damage, and operator injury, particularly in high-load industrial or rescue operations.

Applications of Snatch Blocks

Construction and Utility Work

Snatch blocks are commonly used in construction and utility projects to lift and move heavy components efficiently. Typical applications include:

● Lifting beams during building assembly.

● Raising transformers for electrical installations.

● Handling utility poles safely on site. The use of lifting and pulling tools in conjunction with snatch blocks improves load control by distributing forces evenly, reducing stress on ropes and hoists, and allowing operators to maneuver heavy materials with precision.

Rescue and Emergency Operations

In rescue scenarios, snatch blocks facilitate the safe movement of heavy objects. They allow responders to:

● Lift or reposition debris or collapsed materials in disaster zones.

● Stabilize loads when removing vehicles or obstacles from critical areas. Example setups often involve anchoring the snatch block to a stable structure and configuring a pulley system to maximize mechanical advantage, maintaining safety and load stability throughout the operation.

Vehicle Recovery

Snatch blocks play a key role in off-road vehicle recoveries, enabling controlled extraction of stuck vehicles. Applications include:

● Performing double-line pulls to increase winch effectiveness.

● Navigating obstacles such as trees, rocks, or uneven terrain.

● Adjusting pull angles to maintain optimal force application. Using a snatch block in these scenarios enhances mechanical advantage without overloading the primary winch, ensuring safer and more efficient recovery operations.

Marine and Dock Applications

On docks and marine vessels, snatch blocks assist in moving cargo and adjusting lines with precision. Benefits include:

● Smoothly lifting or repositioning heavy goods during loading or unloading.

● Protecting ropes from wear by reducing friction and abrasion.

● Maintaining consistent tension and control over loads in dynamic environments. Snatch blocks ensure stable load management while supporting operational efficiency, particularly when multiple lines or varying angles are involved.

Choosing the Right Snatch Block

Material and Durability

Snatch blocks are commonly made from steel, aluminum, or composite materials, each with distinct advantages. Steel blocks provide maximum strength and durability, suitable for heavy-duty industrial lifting. Aluminum blocks are lighter, making them easier to transport while still offering substantial load capacity. Composite blocks are engineered for corrosion resistance and reduced weight, ideal for marine or outdoor applications. When selecting a snatch block, consider weight, strength, and expected operational lifespan, ensuring the material matches the demands of your lifting or pulling tasks.

Rope and Winch Compatibility

Proper rope and winch compatibility is crucial for safe and efficient operation. Snatch blocks must accommodate the type of rope used: synthetic ropes provide flexibility and resistance to kinking, while steel ropes offer high tensile strength. Sheave diameter and groove design must match the rope diameter to prevent excessive wear. Recommended rope diameter ranges and sheave specifications should be verified against manufacturer guidelines to maintain performance and minimize the risk of failure during lifting operations.

Additional Features

Modern snatch blocks include several features that enhance operational flexibility:

● Swivel ends allow the block to rotate and align with changing pull directions.

● Hook designs enable secure attachment to anchors or loads.

● Shackle options provide additional connection points for versatile rigging setups. These features allow operators to adapt snatch blocks to varying angles, load types, and environmental conditions without compromising safety or efficiency.

Maintenance and Inspection

Routine maintenance ensures snatch blocks operate reliably under repeated heavy-load conditions. Key practices include:

● Regular inspections for wear, cracks, or deformation in the sheave, side plates, and casing.

● Alignment checks to ensure the rope runs smoothly and evenly through the sheave.

● Lubrication of moving components to reduce friction and prevent premature wear. Implementing consistent maintenance procedures helps extend the lifespan of the snatch block and ensures predictable performance during critical lifting and pulling operations.

Common Mistakes and How to Avoid Them

Overloading the Snatch Block

Respecting the working load limit (WLL) of a snatch block is critical for safe operations. Exceeding the rated load can cause severe stress on the sheave, side plates, and attachment points. Potential risks include:

● Sudden failure of the block under high tension.

● Rope breakage due to uneven stress or overextension.

● Damage to connected lifting equipment such as winches or hoists. Operators should always verify the WLL before use and ensure the combined weight of the load and applied forces does not exceed this limit.

Incorrect Installation or Threading

Improper installation of a snatch block can compromise safety and performance. Key concerns include:

● Side plates not fully secured, which may allow the rope to slip or pop out.

● Misaligned rope placement causing uneven load distribution and excessive wear.

● Twisted or crossed rope paths that increase friction and reduce mechanical advantage. Ensuring correct threading and locking of the side plates prevents these risks and maintains consistent force transfer.

Poor Anchor Selection

The choice of anchor significantly affects load control and operational safety. Risks associated with unstable anchors include:

● Unexpected movement or failure of the anchor, leading to loss of tension and load instability.

● Increased strain on the snatch block and connected ropes, accelerating wear. Guidance for selecting anchors:

● Use solid, fixed points such as structural beams, utility poles, or vehicles rated for applied forces.

● Avoid loose, weak, or movable objects that cannot withstand dynamic loads.

Ignoring Rope Wear and Winch Limits

Rope condition and winch capacity directly impact the safe use of snatch blocks. Key considerations:

● Damaged or frayed ropes reduce mechanical efficiency and increase the likelihood of failure.

● Exceeding the winch’s rated capacity can place unexpected stress on both the winch and the snatch block. Preventive measures include:

● Routine inspection of rope for fraying, kinks, or cuts.

● Ensuring the winch is appropriately rated for the load and pulling configuration.

● Replacing worn ropes promptly to maintain mechanical advantage and operational safety.

Conclusion

The snatch block is vital for lifting, rigging, and recovery tasks. It provides mechanical advantage, directional flexibility, and enhanced safety. JITAI Electric Power Equipment Co., Ltd. offers snatch blocks that ensure reliable load control and efficient operation.

FAQ

Q: What is a snatch block used for in industrial operations?

A: A snatch block is used to increase mechanical advantage and redirect loads in lifting, rigging, and vehicle recovery.

Q: When should a snatch block be deployed on a job site?

A: Use a snatch block when a load exceeds single-line capacity or requires directional change for safe handling.

Q: How does a snatch block impact equipment strain?

A: It distributes forces across lines, reducing stress on winches, lever hoists, and hand pullers.

Q: What are key maintenance considerations for a snatch block?

A: Regularly inspect sheaves, side plates, and attachment points for wear and proper alignment to ensure safe operation.

Q: Are there trade-offs when using multiple snatch blocks?

A: Multi-line pulls with snatch blocks increase load capacity but reduce line speed and require longer rope lengths.