The Nylon Snatch Block is engineered to simplify heavy-duty lifting and line-pulling operations. Its robust alloy-steel frame holds a high-strength nylon sheave, which delivers a smoother rotation and longer service life than traditional steel wheels.

Each block is lubricated before assembly to minimize wear and ensure consistent performance over time.

The swivel hook or eye fitting allows for easy attachment and flexible rigging setups, making it an essential tool for mechanical, marine, and electrical power projects.

From a single-sheave 1-ton block to a multi-sheave 15-ton configuration, this product line offers versatility for multiple lifting needs — whether you’re hoisting equipment on a jobsite, rerouting cables, or managing tension in line-pulling systems.

Product Features & Highlights

Durable Construction: Main components made from heat-treated alloy steel, exceeding national safety standards.

Smooth Operation: Integrated rolling bearings reduce friction and improve sheave rotation efficiency.

Longer Service Life: Factory-lubricated components extend lifespan and minimize maintenance requirements.

Corrosion Resistance: Nylon sheaves and anti-rust surface treatment protect against harsh weather or marine exposure.

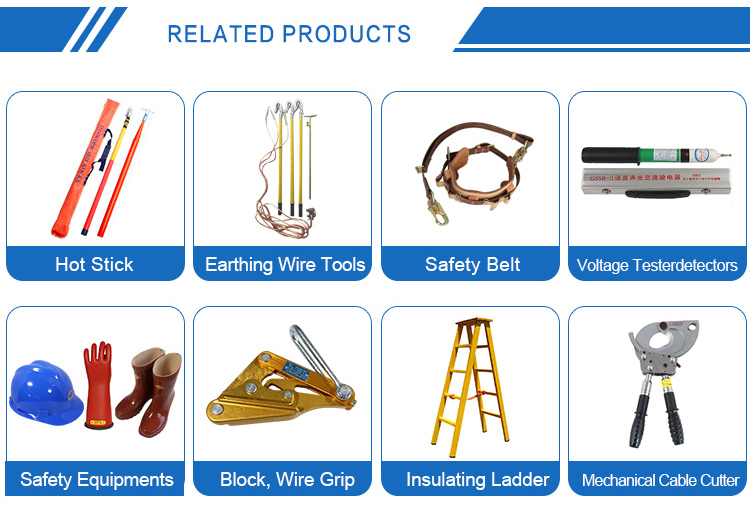

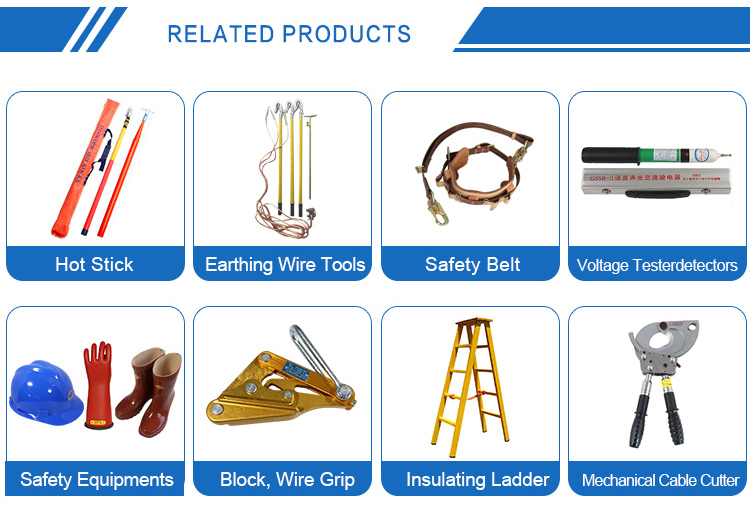

Flexible Options: Available in hook, ring, or plate-mount styles to fit diverse installation setups.

High Load Capacity: Supports lifting capacities from 10 kN to 150 kN, suitable for professional-grade rigging work.

Applications

Construction & Infrastructure: For lifting steel components and concrete segments.

Power Transmission Projects: Ideal for guiding cables and tensioning lines.

Marine & Offshore Use: Resists corrosion and ensures smooth operation in humid environments.

Utility & Maintenance Work: Simplifies pulley-based lifting and equipment relocation.

Forestry & Recovery Operations: Suitable for winch and towing systems requiring controlled load movement.

Material & Structure

| Component | Material | Description |

| Frame Body | Alloy Steel | High-strength body offering load stability and durability |

| Sheave | Nylon (engineering-grade) | Lightweight, smooth, corrosion-resistant surface reduces cable wear |

| Bearing | Sealed Rolling Bearing | Ensures frictionless rotation and stable performance |

| Hook/Eye | Forged Steel | Optional swivel hook, eye ring, or plate mount available |

| Finish | Zinc Plated / Painted | Surface treatment enhances corrosion protection and appearance |

Technical Parameters

| Model | Capacity (kN) | Rope Dia (mm) | Weight (kg) | Configuration | Hook Type | Ring Type | Plate Type |

| QH1-1 (1 T) | 10 | 7.7 | 2.8 | Single Sheave | G | H | – |

| QH1-2 (1 T) | 10 | 6 | 2.8 | Double Sheave | G | H | – |

| QH1-3 (1 T) | 10 | 6 | 4.1 | Triple Sheave | G | H | – |

| QH2-1 (2 T) | 20 | 9.3 | 4.2 | Single Sheave | G | H | – |

| QH2-2 (2 T) | 20 | 7.7 | 6 | Double Sheave | G | H | – |

| QH2-3 (2 T) | 20 | 7.7 | 4.2 | Triple Sheave | G | H | – |

| QH3-1 (3 T) | 30 | 11 | 7 | Single Sheave | G | H | B |

| QH3-2 (3 T) | 30 | 9.3 | 5.3 | Double Sheave | G | H | – |

| LH3-3 (3 T) | 30 | 7.7 | 6.5 | Triple Sheave | G | H | – |

| QH5-1 (5 T) | 50 | 13 | 9.6 | Single Sheave | G | H | – |

| QH5-2 (5 T) | 50 | 11 | 10.8 | Double Sheave | G | H | – |

| QH5-3 (5 T) | 50 | 9.3 | 12.5 | Triple Sheave | G | H | – |

| QH8-1 (8 T) | 80 | 17 | 7.7 | Single Sheave | G | H | B |

| QH8-2 (8 T) | 80 | 13 | 17 | Double Sheave | H | H | – |

| QH8-3 (8 T) | 80 | 11 | 15.5 | Triple Sheave | H | H | – |

| QH10-1 (10 T) | 100 | 18.5 | 25 | Single Sheave | G | H | B |

| QH10-2 (10 T) | 100 | 13 | 18.5 | Double Sheave | H | H | – |

| QH10-3 (10 T) | 100 | 11 | 20 | Triple Sheave | H | H | – |

| QH15-1 (15 T) | 150 | 21.5 | 34 | Single Sheave | H | H | B |

| QH15-2 (15 T) | 150 | 17 | 22 | Double Sheave | H | H | – |

| QH15-3 (15 T) | 150 | 13 | 26 | Triple Sheave | H | H | – |

| QH15-4 (15 T) | 150 | 11 | 30 | Four Sheave | H | H | – |

Quality & Safety

All snatch blocks are produced under ISO 9001 certified quality systems.

Each unit is load-tested to ensure compliance with rated capacity and safety factors.

Lubrication points are sealed to prevent contamination and rust.

Meets or exceeds international safety standards for lifting hardware.

Optional material certificates and inspection reports are available upon request for bulk orders.

Why Choose Us

Over 15 Years of Manufacturing Experience in rigging and lifting hardware.

OEM & ODM Services: Custom designs, branding, and packaging for industrial distributors.

Competitive B2B Pricing: Direct factory supply ensures cost-effectiveness without quality compromise.

Global Shipping & After-Sales Support: Delivered to major markets in North America, Europe, and Asia.

Strict QC Process: Each batch is 100% inspected for dimensional accuracy and load performance.

FAQ

Q1: Can these nylon snatch blocks be customized for specific rope diameters or loads?

A1: Yes. We support customization of wheel size, rope diameter, and mounting type to meet different working loads or system requirements.

Q2: What is the difference between hook, ring, and plate types?

A2: The hook type offers quick connection; ring type provides fixed installation; plate type allows bolting directly onto machinery or frames.

Q3: Are these blocks suitable for marine environments?

A3: Absolutely. The nylon sheave and anti-corrosion coating make them ideal for coastal or offshore conditions.

Q4: Do you provide quality certificates or test reports?

A4: Yes, we can issue load test reports, ISO certificates, and material composition reports upon request.

Q5: What is your minimum order quantity (MOQ)?

A5: For standard models, MOQ is 50 pcs; for OEM orders, it depends on the design and packaging requirements.