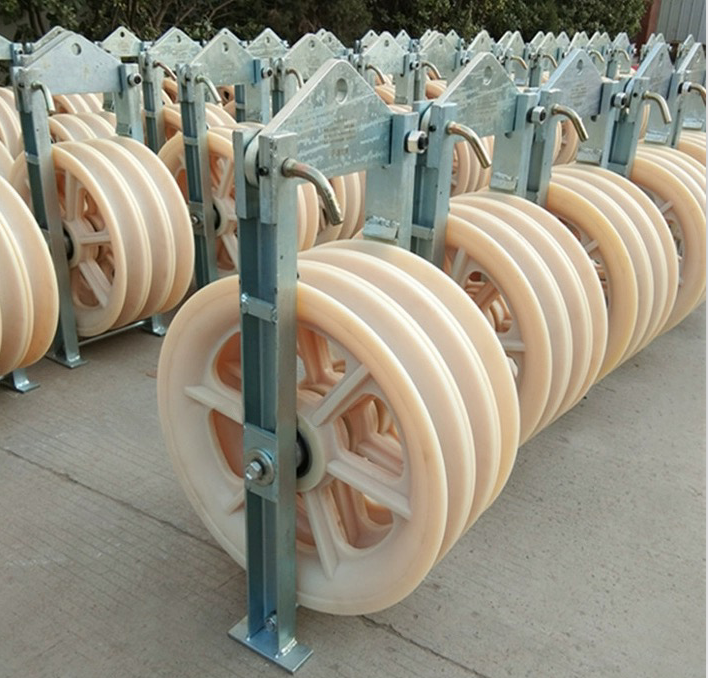

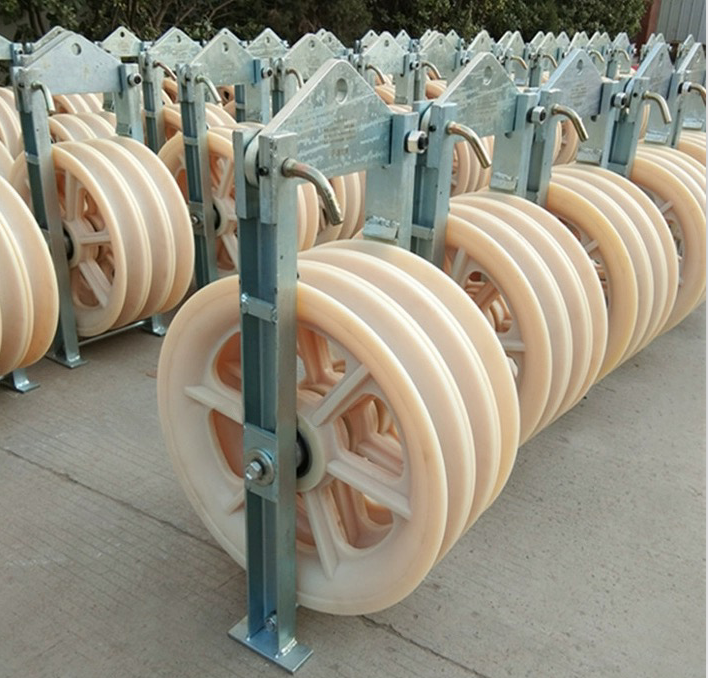

In real-world lifting and pulling scenarios, friction is more than just an inconvenience—it leads to heat buildup, rope damage, unstable movement, and long-term safety risks. Nylon Snatch Pulley Blocks are designed specifically to eliminate these pain points.

At the heart of the block is a precision-molded nylon wheel. Unlike metal sheaves, nylon offers a smooth, almost dampened contact surface that gently guides wire rope or fiber rope. When the load moves, the wheel rotates with a soft, controlled motion rather than a harsh metallic scrape. This not only protects the rope but also creates a noticeably quieter operation—an important advantage on job sites where operators rely on sound cues to judge load behavior.

The robust steel side plates and reinforced hook or shackle connection provide confidence under load. When held, the block feels balanced and dense, signaling strength without unnecessary bulk. During operation, the opening mechanism allows quick rope insertion, reducing downtime and improving workflow efficiency for crews handling frequent rigging changes.

These pulley blocks are not designed for one-off tasks. They are built for repeat use in professional environments, where reliability, consistency, and safety are non-negotiable.

Product Features & Highlights

Low-Friction Nylon Wheel

The nylon sheave minimizes friction, reducing heat buildup and extending rope life, especially in continuous or heavy-duty pulling operations.

Quiet, Smooth Load Redirection

Compared with traditional steel wheels, nylon delivers a noticeably quieter and smoother rotation, improving operator control and site comfort.

High-Strength Load-Bearing Structure

Reinforced side plates and precision assembly ensure stable performance under rated working loads.

Quick-Access Snatch Design

Side-opening structure allows fast rope installation without fully disconnecting the line, saving time in the field.

Corrosion-Resistant Construction

Suitable for outdoor, marine, and utility environments where moisture and dust are unavoidable.

Common Industry Application Scenarios

Lifting & Rigging Operations

Used in cranes, hoists, and manual lifting systems to redirect load paths and improve mechanical advantage.

Power & Utility Maintenance

Ideal for overhead line work, cable stringing, and pole installation where controlled load movement is critical.

Marine & Port Equipment

Nylon wheels perform reliably in humid and salt-prone environments while protecting expensive ropes.

Construction & Infrastructure Projects

Supports repeated heavy lifting cycles without excessive wear, helping reduce long-term equipment costs.

Material & Structural Design Advantages

Rather than relying solely on thicker steel, these pulley blocks adopt a material-efficiency approach. The nylon wheel absorbs micro-vibrations and reduces contact stress, while the metal frame handles structural load. This division of labor between materials improves overall durability.

From a tactile perspective, the surface finish feels smooth and industrial-grade, free from sharp edges that could damage gloves or ropes. During movement, the rotation is controlled and stable, preventing sudden jerks that can compromise safety.

This design philosophy reflects real-world B2B usage: equipment that must perform reliably, repeatedly, and predictably.

Technical Specifications

| Parameter Item | Description |

| Product Name | Nylon Snatch Pulley Blocks |

| Wheel Material | High-strength nylon |

| Body Material | Carbon steel / alloy steel |

| Structure Type | Side-opening snatch block |

| Load Direction | Single sheave redirection |

| Application Rope Type | Wire rope / fiber rope |

| Surface Treatment | Anti-corrosion finish |

| Usage Environment | Indoor & outdoor industrial use |

Safety & Performance Considerations

Designed to maintain stable rotation under rated load

Nylon wheel reduces sudden load shock

Clear load path improves operational visibility

Compatible with standard rigging practices and safety protocols

For B2B buyers, this translates to fewer replacements, lower downtime, and improved on-site safety compliance.

Why Choose Us

Choosing a pulley block supplier is not just about price—it is about trust, consistency, and technical understanding.

Manufacturing Experience

We understand real industrial use cases and design products accordingly.

B2B-Oriented Quality Control

Each pulley block is produced with consistency in load performance and material integrity.

Clear Technical Communication

Our product documentation is structured to support procurement teams, engineers, and project managers.

Custom & Bulk Supply Capability

Suitable for long-term projects and repeat procurement cycles.

Frequently Asked Questions

Q1: Is a nylon wheel strong enough for heavy-duty applications?

Yes. The nylon used is engineered for high load-bearing performance while reducing friction and rope wear.

Q2: Can this pulley block be used outdoors?

Absolutely. The corrosion-resistant body and nylon wheel make it suitable for outdoor and marine environments.

Q3: What type of rope is compatible?

Both wire rope and fiber rope can be used, provided they match the rated capacity.

Q4: Is this product suitable for continuous operation?

Yes. The low-friction design helps manage heat and wear during repeated or prolonged use.

Q5: Can specifications be customized for large orders?

Customization options may be available depending on order volume and application requirements.