Electrical safety is a critical concern in environments where electricity is used, particularly in high-voltage settings. One of the most essential tools for ensuring the safety of electrical workers is the grounding stick. This tool serves as a critical safety measure, helping to safely discharge electrical energy into the ground, thus preventing dangerous electrical shocks or other hazardous incidents during maintenance or repair tasks. This article will take a closer look at what a grounding stick is, how it works, and why it is indispensable for electrical safety in high-voltage environments.

Grounding sticks are not just a tool; they are a lifeline for electrical workers, providing protection when dealing with potentially hazardous electrical systems. By understanding the mechanics, applications, and importance of this tool, we can appreciate the critical role it plays in maintaining safety standards in the electrical industry.

1. Definition of a Grounding Stick

A grounding stick is a long, insulated tool used primarily to safely discharge electrical energy into the ground from live electrical circuits. It is designed to facilitate the safe grounding of electrical systems, ensuring that any stray electrical energy is directed away from the worker handling the equipment. Essentially, grounding sticks serve to protect electrical workers from the hazards of electrocution and ensure that any residual voltage is eliminated before work on a circuit or electrical system can begin.

How a Grounding Stick Works

The grounding stick is equipped with a metal rod or conductor, often made of copper or aluminum, which has excellent electrical conductivity. The tool works by attaching one end to a live electrical circuit, while the other end is connected to a grounding point, such as a grounded metal rod or a grounding system. The conductive metal in the stick ensures that any excess or stray electrical charge will safely flow into the ground, neutralizing the danger before any work on the system can commence.

This process of transferring the electrical charge into the earth is essential because it prevents electrical shock or fire hazards from occurring when workers come into contact with the equipment. The insulated handle of the grounding stick ensures that the worker remains safe by preventing electrical current from traveling up the stick into the user's body.

2. Importance of Grounding in Electrical Safety

Grounding as a Safety Measure

Grounding is one of the primary safety mechanisms in electrical systems. It is an essential practice in all electrical installations, whether in residential, commercial, or industrial environments. The main purpose of grounding is to direct any electrical fault current safely into the earth, thus protecting people and equipment from the harmful effects of electrical surges, which could otherwise lead to fatal accidents or significant equipment damage.

Grounding provides a path of least resistance for electrical energy. When a fault occurs, grounding ensures that the electrical energy does not follow unpredictable paths that could harm workers or damage equipment. Instead, it is safely dissipated into the ground, minimizing the risks associated with electrical failures.

Why Grounding is Critical in High-Voltage Environments

In high-voltage environments, such as electrical power plants, substations, or construction sites, the risk of electrical hazards is significantly higher. Electrical equipment in these environments can store large amounts of voltage even after being turned off, and accidental contact with live circuits can result in serious injuries or even fatalities.

By using a grounding stick, electrical workers are able to ensure that the electrical system is properly grounded before any maintenance or repairs are conducted. This is especially important in high-voltage systems where the possibility of residual energy remains even after the power has been cut off. Grounding provides an extra layer of protection, ensuring that workers can safely engage with electrical equipment without the risk of electrical shock.

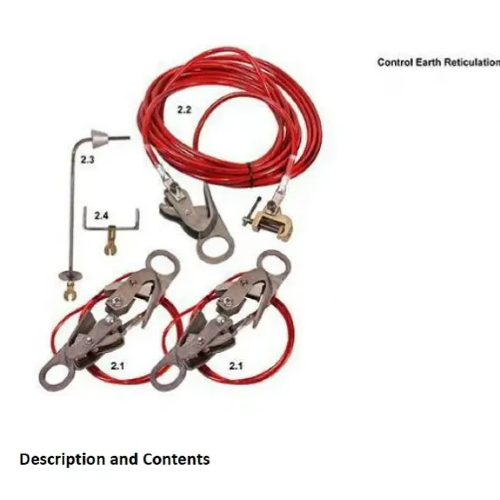

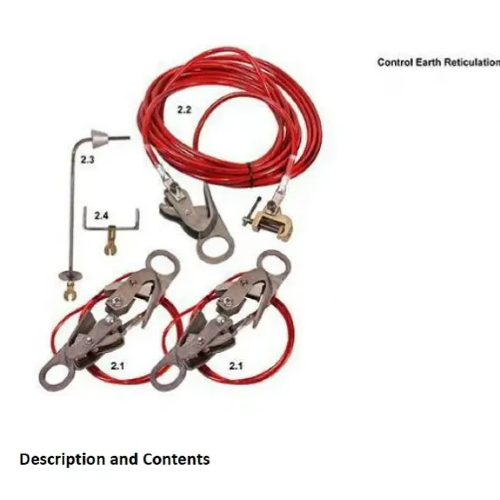

3. Components of a Grounding Stick

A grounding stick consists of several key components, each designed to work together to ensure safe and efficient grounding of electrical systems.

Component | Description |

Insulated Handle | The handle is made from high-quality, durable insulating materials such as fiberglass or plastic. It protects the worker by preventing any electrical current from reaching their body. |

Grounding Clamp | A clamp at the working end of the grounding stick allows it to securely attach to the electrical circuit or equipment. This clamp ensures a stable connection to the system, which is vital for proper grounding. |

Conductive Rod | The conductive rod, often made from copper or aluminum, is the central part of the grounding stick. It carries the electrical current from the live circuit to the grounding point. |

Safety Latches | Some advanced models of grounding sticks include safety latches that provide additional security, ensuring that the grounding clamp stays in place during the grounding process. |

These components work in tandem to ensure that the grounding stick can safely discharge electrical energy, while protecting the worker from electrical hazards. The insulation on the handle is particularly important, as it prevents current from passing through the user in case of an accidental connection with live circuits.

4. How a Grounding Stick Works

The process of using a grounding stick is straightforward, yet crucial for ensuring safety. Here’s a step-by-step guide on how the grounding stick functions:

Preparation: Before using a grounding stick, ensure that all safety measures are in place. Workers should wear appropriate PPE, including insulated gloves and safety boots. The equipment should be powered off, and any other necessary safety steps should be followed according to the standard operating procedure.

Clamping the Grounding Stick: The grounding stick comes with a clamp at one end, which is attached to the electrical system that requires grounding. The clamp should be securely fastened to a conductive point on the system to ensure good contact with the electrical circuit.

Connecting to the Ground: Once the grounding clamp is attached, the other end of the grounding stick—typically a conductive metal rod—is connected to a ground point. This point could be a ground rod embedded in the earth or another type of established grounding system.

Electrical Discharge: The grounding stick completes the circuit by providing a safe pathway for electrical energy to flow from the live electrical system into the ground. This helps prevent dangerous build-ups of voltage and ensures that the electrical equipment is safe to work on.

Removal: After the grounding process is complete, the grounding stick is removed by reversing the process. The grounding clamp is disconnected from the electrical system, and the stick is safely stored for future use.

5. Applications of Grounding Sticks

Grounding sticks are used in various industries and applications where electrical safety is of paramount importance. Here are the most common applications:

Power Generation and Distribution

In power generation facilities, such as power plants and substations, grounding sticks are crucial tools. They ensure that electrical circuits are properly grounded before maintenance or inspection, protecting workers from the potential hazards of electrical faults.

Electrical Maintenance and Repair

For electricians and technicians working on electrical systems, grounding sticks are essential tools for maintaining safety during repairs or inspections. These tools are used to safely discharge any residual energy in the system, ensuring that technicians can safely work on the equipment.

Construction Sites

On construction sites, particularly those where electrical systems are being installed or repaired, grounding sticks are used to ensure the safety of workers. When working with temporary electrical installations, grounding sticks ensure that electrical energy is safely directed into the earth, preventing electrical shock.

6. Types of Grounding Sticks

There are various types of grounding sticks available, each suited to different electrical environments and needs. Below are the most common types:

Manual Grounding Sticks

Manual grounding sticks require the operator to manually set them up and connect them to the live system and the grounding point. These are typically used in residential or light commercial settings.

Automatic Grounding Sticks

Automatic grounding sticks are equipped with mechanisms that automatically clamp onto electrical systems and establish a grounding path. These are ideal for environments that require quick grounding and frequent maintenance, such as industrial plants.

Heavy-Duty Grounding Sticks

Heavy-duty grounding sticks are designed for use in high-voltage environments, such as power stations, where large amounts of electrical energy need to be safely discharged. These sticks are built with extra durability and insulation to handle more significant electrical currents.

7. Benefits of Using a Grounding Stick

Ensures Worker Safety

The primary benefit of grounding sticks is that they help prevent electrical shock. By providing a safe route for electrical energy to discharge, grounding sticks protect workers from hazardous electrical environments.

Prevents Equipment Damage

Grounding sticks not only protect workers, but they also prevent damage to electrical equipment. Grounding helps dissipate excess voltage, which could otherwise cause malfunction or destruction of sensitive equipment.

Compliance with Safety Regulations

Using grounding sticks ensures that workers comply with workplace safety regulations. Many safety standards, including OSHA regulations, require that electrical systems be grounded before workers can safely engage with them. Grounding sticks help meet these legal requirements and maintain a safe working environment.

8. Conclusion

In conclusion, grounding sticks are indispensable tools for ensuring electrical safety, particularly in high-voltage and hazardous environments. They play a vital role in protecting electrical workers by providing a reliable method for safely discharging electrical energy into the ground. Whether used in power plants, electrical maintenance, or construction sites, grounding sticks are essential for safeguarding both personnel and equipment. These tools offer an added layer of security when working with live electrical systems, minimizing the risk of electrical hazards.

At JITAI Electric Power Equipment, we are committed to delivering high-quality grounding solutions and electrical safety products. With our expertise and industry-leading tools, we ensure that electrical professionals can work with peace of mind. To learn more about our products or to discuss your specific requirements, please don't hesitate to contact us. Our team is ready to assist you in choosing the right equipment to meet your needs.

9. FAQ

1. What is the main purpose of a grounding stick?

The main purpose of a grounding stick is to safely discharge electrical energy from live electrical systems into the ground, preventing electrical shocks and ensuring worker safety.

2. Where are grounding sticks commonly used?

Grounding sticks are commonly used in power generation facilities, electrical maintenance, construction sites, and any environment where high-voltage electrical systems are present.

3. Can grounding sticks be used in wet conditions?

Yes, grounding sticks are designed to be safe in various conditions, but it is important to check the specifications for insulation and safety standards to ensure they are suitable for wet environments.

4. How do you properly use a grounding stick?

To properly use a grounding stick, securely attach the grounding clamp to a live electrical system and connect the grounding rod to a designated grounding point. Always follow safety protocols and ensure the tool’s insulation is intact before use.