In daily industrial operations, the real challenge is not pulling—it’s pulling safely, steadily, and repeatedly without fatigue or risk. The 1.5 Ton Tension Ratchet Hand Puller is designed exactly for that moment when controlled force matters more than speed.

From the first grip, the steel handle offers a reassuring weight and balance. Each ratcheting motion produces a clean, mechanical click—an audible confirmation that the load is being tensioned step by step, not forced. This tactile feedback helps operators work with confidence, even in noisy job sites or outdoor environments.

Unlike improvised solutions or overpowered machinery, this ratchet puller allows users to feel the load response in real time, reducing the risk of sudden release, over-tensioning, or material damage. Whether you are aligning heavy components, tightening fencing lines, securing cargo on trailers, or adjusting mechanical assemblies, the tool delivers controlled strength without drama.

This product was developed with B2B users in mind—maintenance crews, logistics providers, construction teams, and equipment installers—who rely on tools that perform consistently across hundreds of cycles, not just the first few uses.

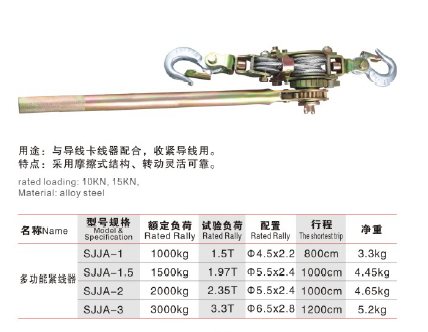

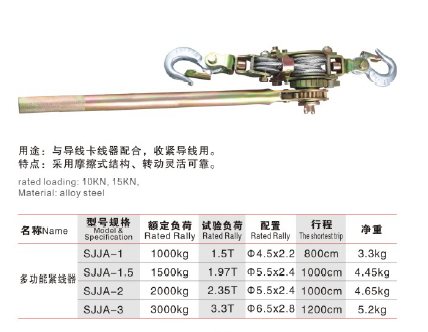

Product Specifications

Product no. | Specification | Steel wire rope length (MM) | Weight (KG) |

SJJA-1 | 1000KG*1M | 1210 | 3.2 |

SJJA-1.5 | 1500KG*1M | 1400 | 3.8 |

SJJA-3 | 3000KG*1M | 1900 | 4.2 |

Key Features & Highlights

Built for Controlled Power

Rated for 1.5 ton working capacity, balancing strength and safety

Progressive ratcheting mechanism prevents sudden load loss

Ideal for tensioning rather than aggressive pulling

Durable Steel Construction

High-strength steel frame resists bending under load

Hardened ratchet gear reduces wear in repetitive use

Corrosion-resistant surface treatment suitable for outdoor conditions

Ergonomic Manual Operation

Comfortable handle geometry reduces hand fatigue

Smooth ratchet engagement minimizes jerky motion

Compact size allows operation in confined spaces

Safety-Oriented Design

Mechanical lock prevents backsliding under tension

Predictable release action enhances operator confidence

Reduces dependency on unstable manual methods

Common Application Scenarios

Cargo securing on flatbeds and utility trailers

Wire, cable, and fencing tensioning

Equipment alignment and positioning

Light structural pulling and adjustment

Industrial maintenance and installation tasks

These scenarios share a common demand: precision over brute force. This ratchet delivers exactly that.

Performance & Reliability in Real Work Conditions

In real-world operations, tools are exposed to dust, moisture, uneven loads, and time pressure. This tension ratchet is engineered to perform consistently under non-ideal conditions.

The ratcheting system maintains stable engagement even when the operator pauses mid-cycle. This prevents load rollback, a critical safety concern in elevated or angled pulling tasks. The steel structure absorbs force without flexing, ensuring that applied effort translates directly into tension rather than wasted motion.

For teams working in shifts, this consistency reduces training time—operators quickly develop trust in how the tool behaves. Over months of use, reduced mechanical play means predictable performance, which directly lowers maintenance costs and replacement frequency.

Manufacturing Quality & Compliance Considerations

This product follows a manufacturing philosophy focused on repeatable precision rather than decorative features. Every structural component is selected to meet strength and durability requirements under rated loads.

Controlled material sourcing for steel components

Load-focused structural design rather than lightweight shortcuts

Compatibility with standard industrial safety practices

For B2B buyers, this means fewer surprises during audits, inspections, or long-term deployment.

Why Choose Us

B2B-Focused Manufacturing Experience

We understand that industrial buyers value consistency, documentation, and supply stability over novelty.

Stable Quality Across Batches

Products are manufactured under controlled processes to minimize variation.

OEM & Customization Support

We support branding, packaging, and specification adjustments for distributors and project-based buyers.

Long-Term Supply Reliability

Designed not just for one shipment, but for sustained procurement relationships.

Technical Communication Support

Clear specifications and responsive technical assistance help reduce pre-sale and post-sale friction.

Frequently Asked Questions

Q1: Is this ratchet suitable for lifting loads vertically?

This product is designed primarily for tensioning and controlled pulling. Vertical lifting should only be performed within safety guidelines and local regulations.

Q2: Can it be used outdoors long-term?

Yes. The steel construction and surface treatment support outdoor use, but regular inspection is recommended in harsh environments.

Q3: What industries typically use this product?

Logistics, construction, fencing, equipment installation, and industrial maintenance are common users.

Q4: Is OEM branding available?

Yes. Custom logos, packaging, and documentation can be supported for bulk and long-term orders.

Q5: How does it compare to automatic tensioning systems?

Manual ratchets offer better tactile control, lower maintenance, and higher reliability in environments without power access.