Every electrical job starts with one critical question: Is this circuit live?

The LV Voltage Detector answers that question quickly, clearly, and without physical contact.

Unlike traditional contact testers that require direct probing, this detector allows users to verify voltage presence simply by approaching the target conductor. A combination of high-sensitivity induction technology, bright LED indicators, and audible alarms provides immediate feedback, even in noisy or low-light environments.

The insulated epoxy resin body feels solid and reassuring in hand. Its smooth surface, balanced weight, and telescopic design make it comfortable for prolonged use and safe when accessing tight or elevated spaces. When voltage is detected, the alert is unmistakable—there is no need to second-guess readings or interpret complex displays.

Designed for routine inspections, fault checks, and pre-maintenance safety confirmation, the LV Voltage Detector becomes a natural extension of an electrician’s workflow, helping teams work faster while significantly reducing electrical risk.

Key Features & Highlights

Non-Contact Voltage Detection

Eliminates the need for direct electrical contact, reducing shock risk during testing.

Instant Visual & Audible Alerts

Bright LED indication paired with a clear sound signal ensures voltage status is recognized immediately.

High-Insulation Epoxy Housing

Durable, impact-resistant, and engineered for electrical safety in professional environments.

Self-Test Function

Built-in self-check ensures the detector is operational before every use, improving reliability on site.

Lightweight & Telescopic Design

Easy to carry, easy to extend, and comfortable for repeated daily operation.

Low-Voltage Focused Sensitivity

Optimized for common electrical maintenance tasks in low-voltage systems.

Application Scenarios

The LV Voltage Detector is designed to support professionals across a wide range of low-voltage electrical environments:

Electrical panel inspection before maintenance

Outlet and socket voltage verification

Cable and wire identification

Industrial equipment servicing

Facility maintenance and safety checks

Construction and renovation electrical work

By providing fast confirmation of live or non-live status, the detector helps prevent accidental contact, reduces downtime, and supports safer work practices.

Safety, Reliability & Compliance

Electrical safety tools must be trusted without hesitation. This LV Voltage Detector is designed with that responsibility in mind.

High-insulation materials help protect users from accidental exposure

Clear signal design minimizes misinterpretation

Self-test capability ensures functional readiness

Compliance with relevant electrical standards supports professional and industrial use

The tool is intended to act as a first-line safety confirmation device, forming part of standard lockout-tagout and inspection procedures.

Ergonomic & Industrial Design

From the moment it is picked up, the detector communicates purpose and reliability.

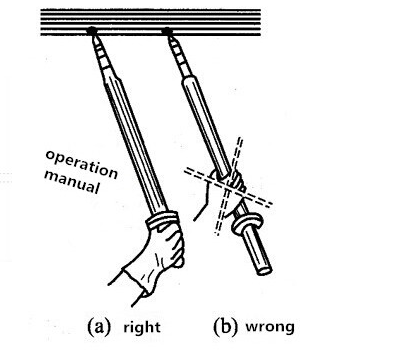

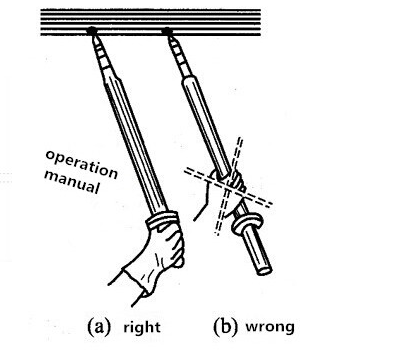

The surface is smooth yet firm, offering a confident grip even when wearing gloves

The telescopic structure allows safe distance from live components

Compact form factor fits easily into tool belts or maintenance kits

Balanced weight reduces fatigue during repeated testing

This design focus ensures the detector supports real-world workflows rather than slowing them down.

Product Specifications

| Parameter | Description |

| Product Name | LV Voltage Detector |

| Voltage Detection Range | 0.1 kV – 10 kV |

| Detection Method | Non-contact induction |

| Alarm Type | Visual LED + Audible sound |

| Housing Material | High-insulation epoxy resin |

| Structure | Lightweight, telescopic design |

| Function | Live voltage detection |

| Self-Test | Supported |

| Applicable Standard | DL740-2000, IEC standard |

| Application | Low-voltage electrical inspection |

Why Choose Us

Focused on Professional Use

Our products are designed for electricians, technicians, and maintenance teams—not consumer shortcuts.

Safety-Driven Engineering

Every design decision prioritizes electrical safety and operational clarity.

Consistent Manufacturing Quality

Stable production processes ensure reliable performance across batches.

B2B Supply Experience

We understand procurement needs, documentation requirements, and long-term cooperation expectations.

Responsive Technical Support

Support before and after purchase for product selection, usage, and integration.

Frequently Asked Questions

Q1: Is this detector suitable for daily professional use?

Yes. It is designed specifically for repeated use in electrical maintenance and inspection tasks.

Q2: Does it require direct contact with the conductor?

No. The detector works through non-contact induction, reducing risk during testing.

Q3: How do I know the device is working before use?

The built-in self-test function allows users to confirm operational status prior to testing.

Q4: Can it be used in noisy environments?

Yes. The combination of visual LED indicators and audible alarms ensures clear feedback.

Q5: Is this suitable for low-voltage systems?

Yes. The detector is optimized for low-voltage electrical inspection scenarios commonly encountered by electricians and maintenance personnel.