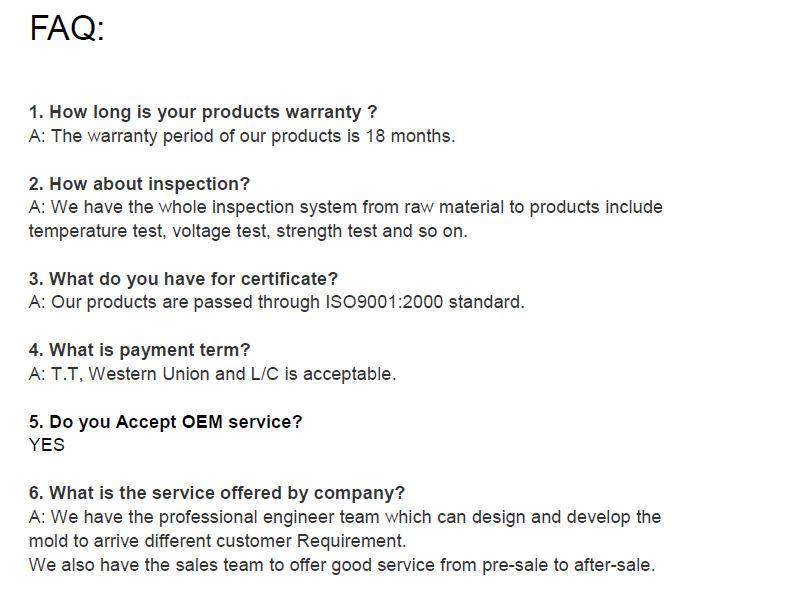

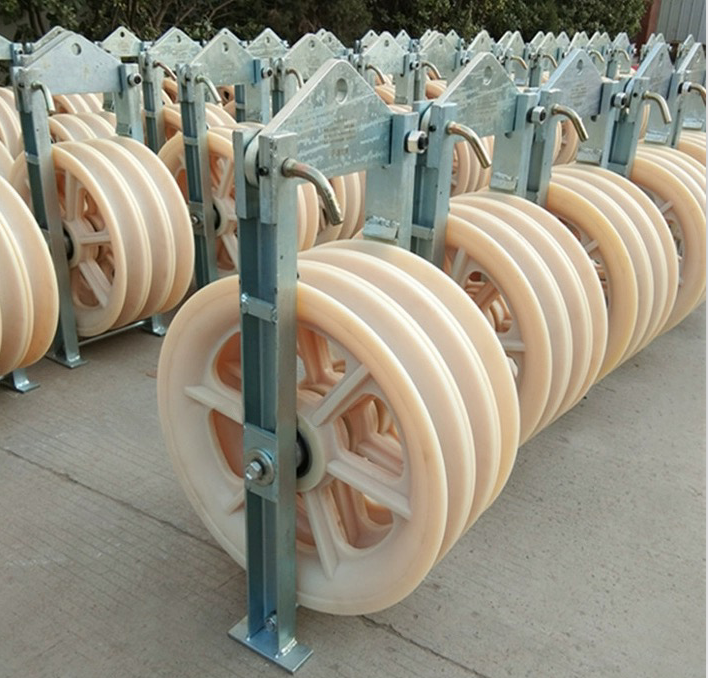

In real-world stringing and lifting operations, efficiency is often lost to friction, instability, and premature equipment wear. The Three Wheel Pulley Block is built to eliminate those pain points. From the moment tension is applied, the triple-wheel configuration works in harmony to guide the conductor smoothly, minimizing resistance and preventing sudden load shifts that can damage cables or slow progress.

The nylon wheels offer a firm yet forgiving surface. They feel solid to the touch, resist deformation under load, and glide quietly even during continuous operation. Unlike metal sheaves that can scrape or fatigue conductors over time, nylon provides a protective interface that preserves the integrity of aluminum and steel-core cables alike.

Structurally, the reinforced frame delivers confidence. When suspended overhead or anchored during stringing, the pulley block maintains alignment and balance. Operators experience less vibration, smoother motion, and more predictable control—critical advantages in high-risk or high-elevation environments. Over time, this translates into faster job completion, fewer replacements, and reduced labor fatigue.

This pulley block is not just a component; it is a reliability tool designed for professionals who cannot afford failure in the field.

Key Features & Highlights

Triple Sheave Load Distribution

Three wheels share the working load, reducing pressure on any single point and extending both cable and pulley lifespan.

Nylon Wheel Construction

Smooth, wear-resistant nylon minimizes friction and protects conductors from surface damage during tensioning and pulling.

Stable Frame Design

The rigid metal body maintains alignment under load, reducing sway and enhancing operational safety.

Low-Noise, Smooth Operation

The pulley glides quietly and consistently, improving on-site communication and operator focus.

Outdoor-Ready Durability

Designed to withstand dust, moisture, and temperature variation common in construction and utility environments.

Technical Specifications

| Parameter | Specification |

| Product Name | Three Wheel Pulley Block |

| Wheel Quantity | 3 |

| Wheel Material | Nylon |

| Application | Conductor stringing, lifting, guiding |

| Structure | Heavy-duty reinforced frame |

| Use Environment | Outdoor / Industrial |

| Compatibility | Power line conductors and cables |

Typical Applications

This Three Wheel Pulley Block is widely used across industries where controlled cable movement and load stability are essential:

Power transmission and distribution line stringing

Utility and electrical infrastructure construction

Industrial lifting and rigging systems

Cable guiding in confined or elevated workspaces

Temporary or permanent stringing setups on job sites

Each application benefits from smoother cable travel, reduced friction loss, and improved safety margins.

Performance Advantages in Real Operations

What sets this pulley block apart is how it performs over time. In continuous stringing operations, single-wheel pulleys often concentrate wear and create uneven tension. By contrast, the three-wheel system spreads mechanical stress evenly, allowing cables to move naturally without grinding or abrupt resistance.

Operators notice the difference immediately. Pulling force feels more consistent, adjustments are easier to control, and cable surfaces remain intact even after repeated passes. These performance gains reduce downtime, lower replacement costs, and support safer workflows—advantages that matter most to professional B2B buyers managing multiple projects.

Quality, Safety & Reliability

Built with field conditions in mind, the pulley block prioritizes operational safety. The stable frame geometry minimizes unexpected movement, while the nylon wheels maintain grip without damaging cable jackets. This balance between strength and protection supports safer lifting practices and helps teams meet project safety standards.

Each unit is manufactured under strict quality controls to ensure dimensional accuracy, load consistency, and long service life. The result is equipment that performs reliably across multiple job cycles, even in demanding environments.

Why Choose Us

Choosing the right pulley block supplier impacts not only performance but also project timelines and cost control.

Industry-Focused Manufacturing

We specialize in lifting and stringing solutions designed for real industrial use, not generic hardware.

Consistent Quality Standards

Every pulley block follows standardized production and inspection processes.

B2B-Oriented Support

We understand procurement cycles, bulk requirements, and project-based purchasing.

Custom and OEM Capability

Specifications, packaging, and branding support available for long-term partners.

Proven Export Experience

Products are supplied to international markets with stable quality and documentation support.

Frequently Asked Questions

Q1: What makes a three wheel pulley better than a single wheel design?

A three-wheel pulley distributes load more evenly, reduces friction, and minimizes wear on both the pulley and the cable, especially in long or continuous stringing operations.

Q2: Is nylon strong enough for industrial applications?

Yes. Industrial-grade nylon offers excellent load-bearing capacity, abrasion resistance, and conductor protection while maintaining smooth movement.

Q3: Can this pulley block be used outdoors for extended periods?

The design is suitable for outdoor environments and typical construction conditions, including dust and moisture exposure.

Q4: Is this product suitable for B2B bulk purchasing?

Absolutely. The pulley block is designed for project-based procurement and long-term industrial use.

Q5: Can specifications be customized?

Customization options may be available depending on order volume and technical requirements.