The Portable Earthing and Short Circuit Kit is engineered for use by linemen, substation technicians, and power system engineers when working on de-energized or faulted electrical networks. Its purpose is to provide a safe and effective path to earth, preventing the re-appearance of dangerous voltages caused by residual or induced currents.

Every detail of this system—from the copper grounding wires to the precision-machined clamps—has been developed for reliability and ease of use in the field. When connected, the kit immediately discharges any residual energy and maintains a stable grounding path, safeguarding both personnel and equipment.

The design prioritizes durability, ease of deployment, and long-term service life. Whether you are working on transmission lines, transformers, or switchgear maintenance, this equipment offers dependable protection under all weather and field conditions.

Features and Highlights

High-Voltage Protection – Ensures complete protection for systems rated up to 33 kV, providing safety against accidental energization and electrical shock.

Premium Conductivity – Manufactured using pure multi-strand copper wire for excellent current carrying capacity and minimal resistance.

Rugged Construction – The phase clamps are made of high-strength aluminum alloy compression, while the earth clamp uses solid brass, ensuring firm, corrosion-resistant connections.

Insulated Fiberglass Rods – Lightweight, non-conductive rods allow safe installation and removal even in challenging field environments.

Weather-Resistant Protective Cover – Designed to perform reliably from –40 °C to +40 °C, suitable for both indoor and outdoor applications.

Fast Connection Design – “Snap-on” clamps and quick-fit connectors minimize setup time, reducing operator fatigue and increasing efficiency on site.

Portability and Storage – Compact and lightweight for easy transport, with organized cable management and carrying case options.

Technical Parameters

| Item | Specification |

| Clamp (Phase) | Aluminum alloy compression type |

| Earth Clamp | Brass material |

| Insulating Stick | Glass-fiber reinforced |

| Conductors | Pure copper multi-strand wire |

| Protective Cover Temperature Range | up to +40 °C |

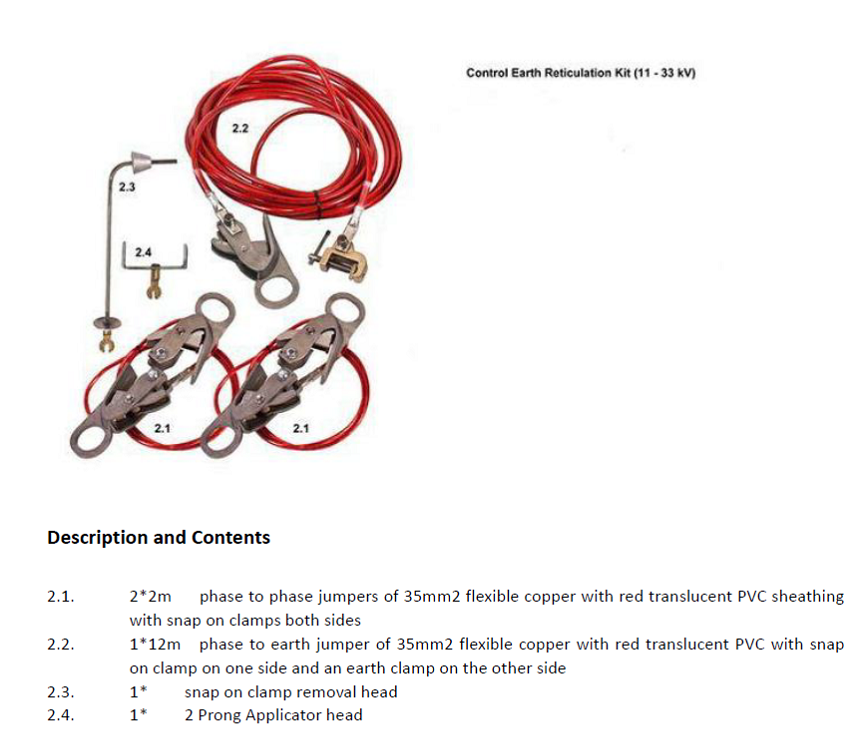

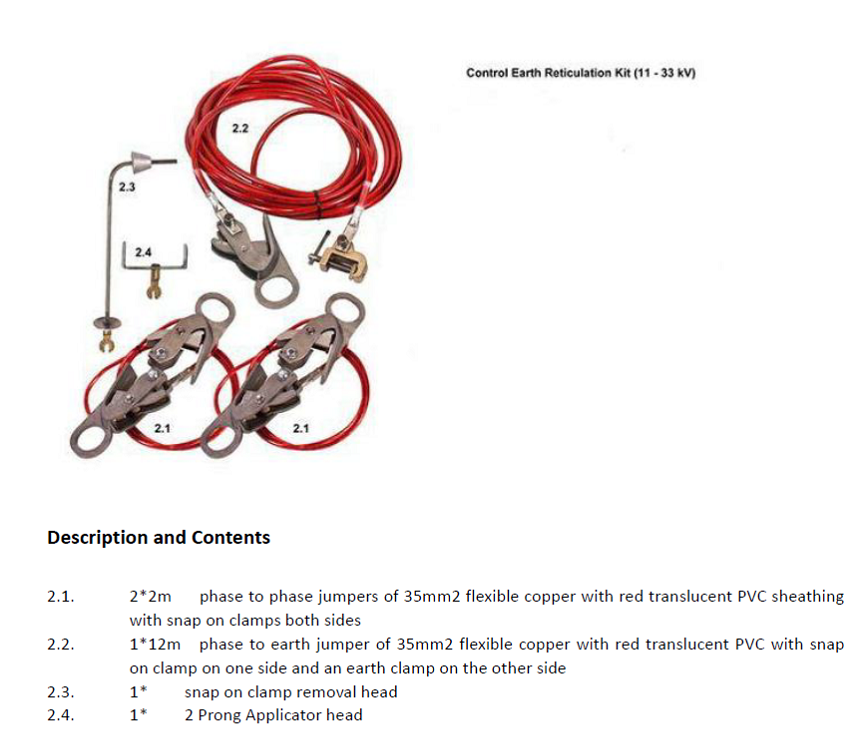

| Jumper Wires | 2 × 2 m phase-to-phase jumpers (35 mm² flexible copper, red PVC sheath) |

| Earth Jumper | 1 × 12 m phase-to-earth jumper (35 mm² flexible copper, red PVC sheath) |

| Connectors | Snap-on clamps on both sides |

| Accessories | Snap-on clamp removal head, 2-prong applicator head |

| Rated Voltage Range | 11 – 33 kV |

| Usage | Temporary earthing and short-circuiting of de-energized lines |

Applications

Substation and Transmission Line Maintenance – Prevents accidental back-feeding or induced voltages during routine servicing.

Power Distribution Networks – Ideal for creating temporary grounding on de-energized circuits.

Industrial Power Plants – Used during switchgear testing, transformer installation, or cable terminations.

Utility and Field Service Teams – Essential for field crews working in remote or temporary environments.

Training and Safety Programs – Serves as a reliable demonstration tool for high-voltage safety practices.

Why Choose Us

Expert Manufacturing Experience – More than 15 years in high-voltage safety equipment production.

Strict Quality Control – Each set is tested under simulated high-voltage conditions before shipment.

Customization Options – Wire length, clamp size, and connector types can be tailored to specific system requirements.

Global Standards Compliance – All products meet or exceed international electrical safety regulations.

Comprehensive After-Sales Support – Technical guidance, maintenance advice, and replacement parts readily available.

Our Commitment: We don’t just sell grounding tools—we deliver peace of mind to every technician working near live electrical systems.

FAQ

Q1: What voltage levels can this kit handle?

A: The standard model supports up to 33 kV. Custom designs for higher voltages are available upon request.

Q2: Can I order different cable lengths?

A: Yes. We provide flexible customization for phase-to-phase and phase-to-earth cable lengths according to site requirements.

Q3: How should the equipment be maintained?

A: Inspect cables, clamps, and rods regularly for signs of wear. Store in a dry location and clean with a non-conductive cloth after each use.

Q4: What makes your product different from other suppliers?

A: Our equipment combines precision engineering, tested reliability, and user-friendly design that reduces set-up time and enhances operator safety.

Q5: Do you offer OEM service?

A: Absolutely. OEM branding, customized packaging, and logo printing are available for bulk orders.

Final Summary

The Portable Earthing and Short Circuit Equipment combines durability, reliability, and intelligent design to ensure absolute safety for professionals working on high-voltage systems. With superior materials, field-proven construction, and strict adherence to international standards, it stands as a trusted solution for electrical safety worldwide.