Why Is an Earth Clamp Critical in Electrical Systems?

In today's world, where electricity powers everything from homes and offices to factories and infrastructure, electrical safety is paramount. With increasing demand for uninterrupted and stable power supply, the importance of a well-designed grounding system has never been more significant.

At the heart of every safe grounding setup is a small but essential component: the earth clamp. But what is an earth clamp, and why does it play such a crucial role in protecting electrical systems?

How Earth Clamps Work: Understanding the Mechanism

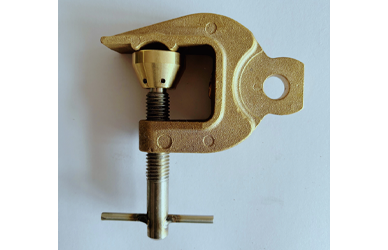

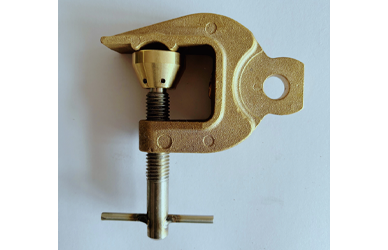

An earth clamp is a mechanical and conductive device used to securely connect an electrical conductor—typically a copper wire or grounding rod—to a grounding system. It forms part of a closed-loop earthing circuit, which allows electrical current to be safely discharged into the earth in the event of a fault.

Key Functions of an Earth Clamp:

Reliable Electrical Connection: Provides low-resistance contact between the conductor and the grounding medium.

Mechanical Stability: Ensures the grounding wire remains firmly in place, even under vibration or environmental stress.

Corrosion Resistance: Withstands moisture, oxidation, and temperature fluctuations for long-term performance.

The clamp is typically installed at critical points in the grounding system, where grounding conductors interface with rods, pipes, rebar, or metallic enclosures. Without this connection, the grounding circuit becomes incomplete, posing serious risks to both equipment and personnel.

The Protective Role of Earth Clamps in Electrical Systems

Earth clamps are more than just mechanical connectors — they are critical components in ensuring the safety, performance, and reliability of any electrical system. From residential homes to industrial substations, proper grounding with earth clamps plays a direct role in preventing accidents and protecting sensitive equipment. Let’s explore how.

1. Electric Shock Prevention

One of the greatest hazards in any electrical system is leakage current, where stray electricity energizes metal parts not meant to carry current. This poses a serious risk: if a person touches a metal chassis or appliance with faulty insulation, the electricity could pass through their body to reach the ground.

An earth clamp mitigates this risk by establishing a safe, low-resistance path to earth. When connected properly, it ensures any fault current is immediately diverted away from people and into the ground. This allows safety devices such as residual current devices (RCDs) or ground fault circuit interrupters (GFCIs) to detect the leakage and shut off power in milliseconds, preventing injury or fatal accidents.

2. Equipment Protection from Voltage Surges

Electrical systems frequently experience voltage surges, whether from internal issues (e.g., switching operations, motor starts) or external events like lightning strikes and grid disturbances. Sensitive equipment — such as servers, programmable logic controllers (PLCs), or medical devices — can be permanently damaged without proper surge management.

By using earth clamps to bond grounding wires securely, excess voltage from surges can be safely discharged into the earth. This protects vital components like:

Control systems and circuit boards

Power transformers

Communication infrastructure

Renewable energy equipment such as solar inverters

Without secure grounding via earth clamps, these high-value assets are exposed to unpredictable and potentially catastrophic electrical stress.

3. System Voltage Stabilization

In any power system, maintaining a stable voltage reference point is essential for safe operation. This is typically done by grounding the neutral point of the transformer or generator.

Earth clamps play a crucial role in creating and maintaining this stable reference. They ensure:

Consistent voltage potential across all grounded components

Reduced risks of floating voltages or unintentional electrical imbalances

More accurate performance from voltage-sensitive devices

Stable voltage helps improve overall power quality, reduces electromagnetic interference (EMI), and supports compliance with grid and safety standards.

4. Effective Operation of Safety Devices

Protective devices such as circuit breakers, fuses, and surge protection devices (SPDs) rely on the presence of a low-impedance ground path to operate correctly. If grounding is incomplete, corroded, or loose due to a poor clamp connection, these devices may not trip when needed — leaving the system vulnerable to:

Prolonged overcurrent conditions

Fires caused by overheated components

Dangerous voltage buildup in exposed equipment

High-quality earth clamps ensure firm, corrosion-resistant, and mechanically strong connections. This continuity enables safety devices to detect faults and interrupt circuits promptly, protecting both people and infrastructure.

Real-World Applications of Earth Clamps

Earth clamps are used across residential, commercial, and industrial settings. Let's examine some common examples where they play a key role in grounding systems:

● Residential Distribution Panels

In homes, the grounding conductor from the main distribution box is often connected to a ground rod buried near the building. Earth clamps are used to bond the wire to the rod securely, ensuring effective current dissipation.

Typical applications include:

Electrical meter grounding

Grounding of household appliances

Protection of rooftop solar systems

● Industrial Power Cabinets and Machine Enclosures

Factories and warehouses have large power distribution cabinets, switchgear, and heavy machinery. These systems must be grounded to prevent shock hazards and ensure equipment longevity.

Earth clamps are used to:

Ground metallic enclosures and equipment frames

Connect copper tape or wire to grounding busbars

Secure earthing cables to structural steel

● Outdoor Equipment and Transformers

Outdoor electrical devices are exposed to rain, temperature swings, and lightning. From HVAC units and transformers to lighting poles and substations, all must be grounded effectively.

Earth clamps help:

Connect earth wires to transformer frames

Bond lightning rods to earth rods or plates

Ground the metallic cases of air conditioners and outdoor machinery

● Construction Sites and Temporary Installations

Temporary electrical networks for construction projects require rapid and reliable grounding systems. Earth clamps offer:

Quick attachment of wires to temporary earth rods

Reusable and adjustable solutions for shifting power setups

Enhanced safety during testing and commissioning stages

Features of a High-Quality Earth Clamp

Not all clamps offer the same performance. The following attributes define a reliable and effective earth clamp:

1. High Conductivity

Made from brass, copper, or stainless steel to ensure minimal resistance and optimal current flow.

2. Corrosion Resistance

Durable under exposure to moisture, salt, and chemicals. Coated or treated materials extend service life.

3. Secure Mechanical Fit

Tight-fitting screws, U-bolt or saddle design prevent slippage and vibration loosening.

4. Easy Installation

No specialized tools required. Threaded bolts and clear markings support quick setup.

5. Durability in Harsh Conditions

Engineered to operate in extreme weather and high-stress environments without degradation.

Best Practices for Using Earth Clamps

To maximize the safety and performance of your grounding system, follow these installation tips:

Use matching materials (e.g., copper clamp with copper wire) to avoid galvanic corrosion.

Tighten connections securely but avoid over-torquing which can strip threads or deform clamps.

Inspect regularly for signs of wear, rust, or mechanical loosening.

Ensure full contact between the conductor and clamp surface for optimal conductivity.

Keep connections dry and sealed, especially in outdoor or corrosive environments.

A Small Device With a Huge Safety Impact

Though compact in size, an earth clamp plays a critical role in electrical safety—ensuring fault currents are safely discharged, protective devices operate quickly, and system voltage remains stable. From preventing electric shock to minimizing equipment damage and fire risks, its function is indispensable.

When planning or upgrading your grounding system, choosing high-quality, corrosion-resistant earth clamps is essential. That’s where JITAI Electric Power Equipment Co., Ltd. stands out—offering durable, precision-engineered earth clamps trusted across construction, energy, and infrastructure sectors.