What is a Snatch Block?

Definition and Basic Functionality

A snatch block is a heavy-duty pulley housed in a metal casing designed to assist in lifting or pulling heavy loads. Unlike a standard pulley, its casing opens, allowing you to easily insert a rope or cable without threading the end through. This unique feature means you can attach the snatch block anywhere along the rope, making it highly versatile.

At its core, a snatch block works by changing the direction of force and increasing mechanical advantage. It redistributes the load, effectively reducing the effort needed to move or lift heavy objects. For example, when recovering a stuck vehicle, a snatch block doubles the pulling power of a winch by allowing the cable to loop back, sharing the load between the winch and the anchor point.

Key Components of a Snatch Block

Pulley (Sheave): The round wheel inside the snatch block that the cable runs over. It reduces friction and allows smooth movement of the rope or cable.

Metal Casing: The protective frame that encloses the pulley. It opens to allow the cable to be inserted or removed easily without untying.

Attachment Point: Usually a hook, shackle, or eyelet, this part connects the snatch block to an anchor, such as a tree saver strap or a vehicle recovery point.

Swivel Mechanism (Optional): Some snatch blocks have a swivel feature allowing the pulley to rotate, which helps align the cable and prevent twisting.

These components work together to provide a durable, efficient tool for heavy lifting and pulling tasks. The snatch block’s design ensures it can handle thousands of pounds of force, making it a critical piece of equipment in off-roading, construction, marine, and industrial applications.

How Do Snatch Blocks Work?

Mechanical Advantage Explained

Snatch blocks create mechanical advantage by reducing the effort needed to move heavy loads. Think of mechanical advantage as the multiplier effect a simple machine gives you. When you use a snatch block in a winching setup, it effectively halves the force required to pull a load.

Here’s how it works: when a winch cable runs through a snatch block and then back to the winch or anchor, the load’s weight is shared between two sections of the cable. This sharing means the winch only needs to exert half the force to move the same load. For example, if a vehicle weighs 4,000 pounds, using a snatch block can reduce the winch’s effort to around 2,000 pounds, doubling the winch’s effective pulling power.

This principle is similar to how a movable pulley works in physics. The snatch block acts as a movable pulley that changes the force direction and reduces the effort needed. Using multiple snatch blocks can increase mechanical advantage even more, cutting the required force further.

Role of Pulleys in Snatch Blocks

The core component of a snatch block is its pulley, also called a sheave. The pulley is a grooved wheel that the cable or rope runs over. It serves two main purposes:

Reducing Friction: The pulley spins freely, letting the cable move smoothly. This reduces friction and wear on the cable, making the pulling process more efficient.

Changing Direction of Force: The pulley can redirect the pull force. For instance, if a stuck vehicle is off to the side, the snatch block can redirect the cable’s pull to align with the winch, allowing recovery from an awkward angle.

Unlike fixed pulleys, snatch blocks open on one side, allowing you to insert the cable without unthreading it. This feature makes them easy to use in the field and versatile for different recovery or lifting setups.

Together, the pulley and the casing of the snatch block enable it to handle thousands of pounds safely. The pulley’s smooth rotation combined with the strong casing ensures the cable moves efficiently while bearing heavy loads.

Types of Snatch Blocks

Snatch blocks come in different designs tailored for specific uses. The two main types you’ll encounter are recovery snatch blocks and industrial snatch blocks. Each serves unique purposes and features distinct characteristics.

Recovery Snatch Blocks

Recovery snatch blocks are built mainly for vehicle recovery and off-roading scenarios. They are designed to handle winch cables and recovery straps safely and efficiently. These snatch blocks usually feature:

Compatibility with Winch Cables: Sized to fit synthetic or steel winch cables commonly used in vehicle recovery.

Loop-End Strap Accommodation: Designed to accept loop-end tree saver straps, ensuring secure attachment to anchor points like trees or recovery points on vehicles.

Heavy-Duty Construction: Made from strong materials such as forged steel or aerospace-grade polymers to withstand high loads, often rated for thousands of pounds.

Compact and Lightweight: Easy to carry in recovery kits, allowing quick deployment in off-road situations.

Safety Features: Some include swivel attachments or sealed bearings to reduce cable wear and improve alignment during pulls.

These snatch blocks help double the pulling power of a winch by redistributing the load. They are essential for off-roaders who frequently recover stuck vehicles or need to maneuver heavy loads in rugged terrain.

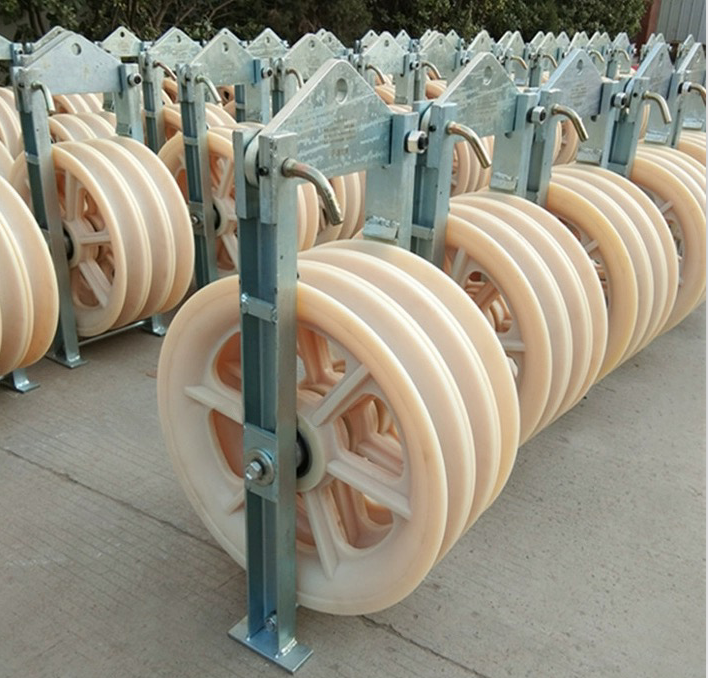

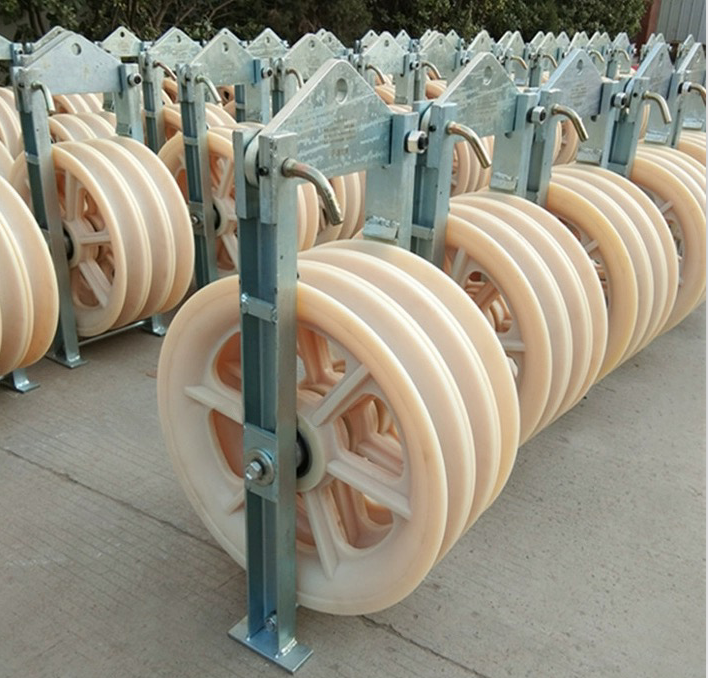

Industrial Snatch Blocks

Industrial snatch blocks are designed for heavy lifting and rigging applications across various industries like construction, marine, and manufacturing. Their features often include:

Higher Load Capacities: Built to handle extremely heavy loads, sometimes tens of thousands of pounds, depending on the model.

Different Attachment Methods: Typically equipped with hooks, shackles, or eyelets suited for cranes, hoists, or fixed rigging points.

Robust Materials: Made from high-grade steel or alloy, often with protective coatings to resist corrosion and wear.

Larger Sheave Sizes: The pulley wheels (sheaves) are bigger to accommodate thicker cables or ropes and reduce friction.

Fixed or Swivel Mounts: Some offer swivel capabilities to align with load direction, minimizing cable twist and wear.

Industries rely on these snatch blocks for lifting heavy materials, redirecting loads, or increasing mechanical advantage in complex rigging setups. They are less portable but vital for safety and efficiency in demanding environments.

Benefits of Using Snatch Blocks

Snatch blocks offer significant advantages that make them indispensable tools in many industries. Their ability to increase load capacity and their versatility across applications are key reasons why professionals rely on them.

Increased Load Capacity

One of the biggest benefits of using a snatch block is its ability to effectively increase the load capacity of your winch or lifting system. By redirecting the cable and doubling the line's length between the load and the anchor point, a snatch block shares the load between two cable sections. This reduces the force required from the winch or lifting device by roughly half, effectively doubling its pulling power.

For example, if your winch has a rated pulling power of 5,000 pounds, adding a snatch block can increase the effective capacity to about 10,000 pounds. This mechanical advantage means you can safely handle heavier loads without upgrading your winch or lifting gear. It also reduces strain on the equipment, extending its lifespan and improving operational safety.

Using multiple snatch blocks in a system can increase mechanical advantage even further. Each additional block can cut the required effort, allowing you to lift or pull loads that would otherwise be impossible or unsafe.

Versatility Across Different Industries

Snatch blocks are incredibly versatile tools. They are used in a wide range of industries, including:

Off-Roading and Vehicle Recovery: Snatch blocks help recover stuck vehicles by increasing winch power and changing pull direction. This is crucial when direct winching is impossible due to terrain or vehicle position.

Construction and Heavy Lifting: In construction, snatch blocks assist cranes and hoists in lifting heavy materials safely and efficiently. They allow operators to maneuver loads around obstacles or into tight spaces.

Marine Applications: Snatch blocks are used on boats and docks to handle heavy lines and equipment, helping to redirect forces and reduce load on winches.

Industrial Rigging: Factories and warehouses use snatch blocks to move heavy machinery or materials, improving load handling and safety.

Their ability to open and close around a rope or cable without unthreading makes them quick and easy to use in the field. This versatility means they can adapt to various load types, cable sizes, and environmental conditions.

Using Snatch Blocks for Vehicle Recovery

Step-by-Step Guide

Using a snatch block during vehicle recovery can greatly increase your winch’s pulling power and make tough recoveries safer and easier. Here’s a simple step-by-step guide to help you set it up correctly:

Position the Recovery Vehicle: Place the recovery vehicle directly across from the stuck vehicle, ideally in a straight line for the best pulling angle.

Attach the Snatch Block: Securely attach the snatch block to a strong anchor point near the stuck vehicle. This could be a tree using a tree saver strap or a recovery point on the stuck vehicle itself. Use a d-ring shackle or similar hardware to secure the snatch block.

Run the Winch Cable: Feed the winch cable from the recovery vehicle through the snatch block’s pulley wheel. The cable should move smoothly through the pulley without twisting.

Return the Cable: Run the cable back to the recovery vehicle and attach it to a secure recovery point.

Begin Winching: Slowly start winching in the cable. The snatch block will double the pulling power by sharing the load between the two cable sections.

Monitor the Setup: Keep an eye on the cable tension and the anchor points. Stop immediately if something looks unsafe or if the cable starts to fray.

Use Multiple Snatch Blocks (Optional): For very heavy vehicles or difficult recoveries, use more than one snatch block to increase mechanical advantage even further.

Following these steps ensures you get the most out of your winch and snatch block setup during vehicle recovery.

Safety Tips and Precautions

Vehicle recovery can be dangerous if proper safety measures aren’t followed. Here are some important safety tips when using snatch blocks:

Check Equipment Ratings: Always verify the working load limit (WLL) of your snatch block and winch cable. They should exceed the vehicle’s weight to avoid failure.

Use a Winch Damper: Place a winch damper or heavy blanket over the cable during recovery. This reduces recoil if the cable snaps, protecting people nearby.

Clear the Area: Make sure bystanders stay well clear of the recovery zone, especially the cable line. A snapped cable can cause serious injury.

Inspect Gear: Before use, inspect the snatch block, cable, shackles, and anchor points for damage or wear. Replace any compromised parts.

Avoid Sharp Angles: Align the cable as straight as possible through the snatch block. Sharp bends increase cable wear and risk failure.

Communicate Clearly: Use hand signals or radios to coordinate between the recovery and stuck vehicle operators.

Winch Slowly: Apply steady, controlled winching force. Sudden jerks can overload the system and cause equipment failure.

Wear Protective Gear: Gloves and eye protection help keep you safe from cable burrs or debris.

By following these safety precautions, you reduce risks and improve the chances of a successful vehicle recovery.

Common Applications of Snatch Blocks

Off-Roading and Vehicle Recovery

Snatch blocks are essential tools for off-roaders and vehicle recovery professionals. When a vehicle gets stuck in mud, sand, or snow, a snatch block can double the pulling power of a winch. It does this by redirecting the cable and sharing the load between the winch and the anchor point. This means the winch works less hard, reducing strain and increasing safety.

Using a snatch block lets you change the direction of the pull, which is helpful when the stuck vehicle isn't directly in front of the recovery vehicle. For example, if the vehicle is stuck at an angle or behind an obstacle, the snatch block can be attached to a tree or solid anchor point to guide the cable around the obstacle. This flexibility makes tricky recoveries possible.

In practice, you attach the snatch block to a strong anchor using a tree saver strap or shackle. Then, run the winch cable through the snatch block and back to the recovery vehicle. This setup effectively doubles the winch’s pulling force. You can even add more snatch blocks to further increase the mechanical advantage, especially for heavier vehicles.

Construction and Heavy Lifting

In construction, snatch blocks play a vital role in lifting and moving heavy materials safely and efficiently. Cranes and hoists use snatch blocks to redirect cables and multiply lifting power. This helps operators maneuver loads around obstacles or into tight spaces without needing larger, more expensive equipment.

Snatch blocks also reduce wear on cables by minimizing friction and preventing sharp bends. This extends the life of lifting gear and improves safety on job sites.

For example, a crane lifting a steel beam might use a snatch block to change the cable’s direction, allowing the beam to be positioned precisely. In rigging setups, snatch blocks can be combined to create complex pulley systems that reduce the effort needed to lift very heavy loads.

Because snatch blocks come in various sizes and load ratings, they can be tailored to specific lifting tasks. Industrial snatch blocks often have higher working load limits and robust construction to handle demanding environments.

Where to Buy Snatch Blocks

Top Brands and Recommendations

When it comes to buying snatch blocks, choosing a reputable brand ensures quality, safety, and durability. Here are some top brands known for their reliable snatch blocks:

Rhino USA: Known for their heavy-duty recovery snatch blocks designed specifically for off-roading. Their products often feature aerospace-grade polymer pulleys and powder-coated forged steel frames. Rhino USA snatch blocks come with high working load limits (often 9,000+ pounds) and lifetime warranties, making them a trusted choice for vehicle recovery enthusiasts.

Warn: A leading name in winching and recovery gear, Warn offers snatch blocks built to withstand tough conditions. Their snatch blocks are compatible with a variety of winch cables and come with robust construction and safety certifications.

Harken: Popular in marine and industrial applications, Harken snatch blocks are known for smooth operation and corrosion resistance. They offer a range of sizes and load ratings suitable for heavy lifting and rigging tasks.

CM (Columbus McKinnon): A well-established industrial brand, CM provides snatch blocks for heavy-duty lifting, often used in construction and manufacturing. Their products meet rigorous safety standards and are designed for long-term durability.

Pewag: Known for high-quality rigging equipment, Pewag snatch blocks are used in various industries including mining, construction, and forestry. They offer a wide range of sizes and load capacities.

When selecting a brand, consider your specific needs, whether for vehicle recovery, industrial lifting, or marine use. Reading customer reviews and checking for certifications like ASME or CE can help ensure you get a safe and reliable product.

Considerations for Purchasing

Before buying a snatch block, keep these factors in mind to ensure you select the right one for your application:

Working Load Limit (WLL): Always choose a snatch block with a WLL that meets or exceeds the maximum load you expect to handle. This is crucial for safety and performance.

Compatibility: Check that the snatch block fits your cable or rope size. Recovery snatch blocks are usually sized for winch cables, while industrial blocks accommodate thicker ropes or cables.

Material and Build Quality: Look for corrosion-resistant materials, such as stainless steel or powder-coated steel, especially if you’ll use the block outdoors or in marine environments.

Pulley Size: Larger sheaves reduce friction and cable wear, which is important for heavy or frequent use.

Ease of Use: Features like an opening side plate or swivel attachment can make installation and operation easier and safer.

Price vs. Quality: While budget matters, don’t compromise safety for cost. Investing in a quality snatch block pays off in reliability and longevity.

Warranty and Support: Brands offering warranties and good customer support provide added peace of mind.

Certifications: Look for products that comply with industry safety standards to ensure they have been tested and approved for heavy-duty use.

Conclusion

A snatch block is a versatile tool that enhances pulling power by redirecting force and doubling winch capacity. It is essential in off-roading, construction, and industrial settings for efficient load handling. When selecting a snatch block, ensure it matches your specific needs and load requirements. JI TAI offers high-quality snatch blocks that provide exceptional value through their durability and efficiency, making them a reliable choice for various applications.

FAQ

Q: What is a Snatch Block?

A: A Snatch Block is a heavy-duty pulley in a metal casing that assists in lifting or pulling heavy loads by changing the direction of force and increasing mechanical advantage.

Q: How do Snatch Blocks increase pulling power?

A: Snatch Blocks double pulling power by allowing the winch cable to loop back, sharing the load between the winch and the anchor point.

Q: Why use Snatch Blocks in vehicle recovery?

A: Snatch Blocks are used in vehicle recovery to double winch power, reduce strain, and change pull direction for safer, more efficient recov