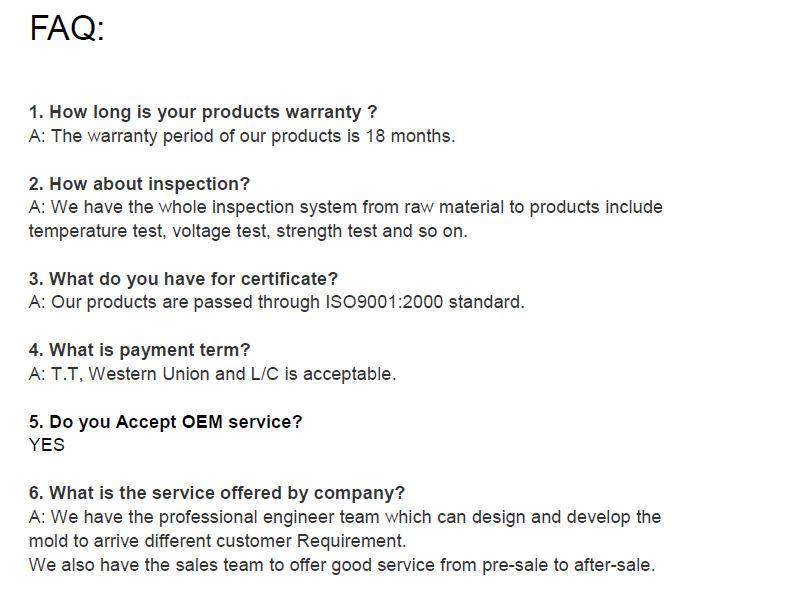

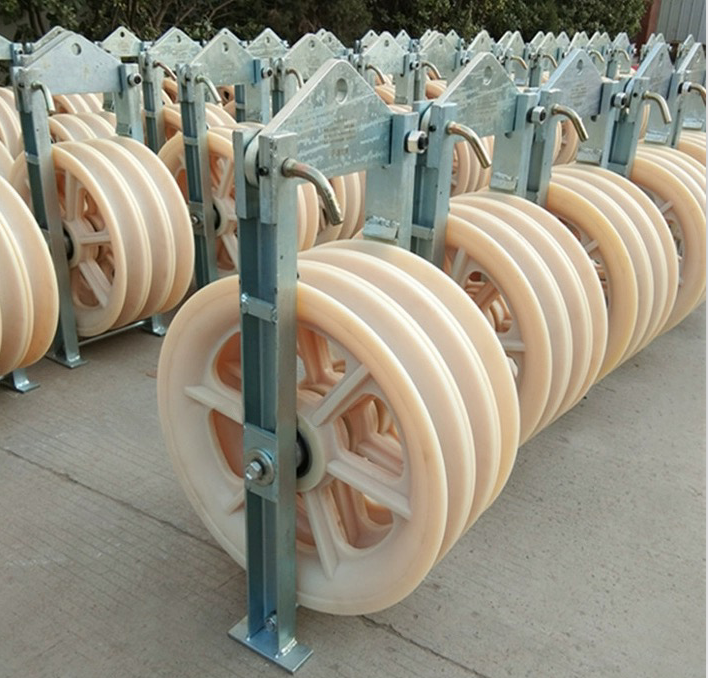

Crafted with a blend of high-strength aluminum alloy and MC nylon, the Stringing Block combines light weight with exceptional durability. The aluminum frame delivers rigidity and corrosion resistance, while the MC nylon sheave provides a smooth rolling surface that minimizes abrasion on cables.

The block can be supplied in hook type or joint plate type, offering flexible mounting options for different working environments. Each sheave runs on precision-sealed bearings, ensuring effortless rotation even under heavy load conditions.

In field operations, whether laying power lines over long spans or handling fiber optic cables in urban installations, this pulley guarantees efficient stringing with reduced manpower and safer cable handling.

Features & Advantages

Smooth Cable Handling:

The MC nylon sheave minimizes cable friction, extending wire life and maintaining insulation integrity.

Lightweight but Strong:

Aluminum alloy structure offers an excellent strength-to-weight ratio, simplifying transport and setup.

Multiple Configurations:

Single, 3-wheel, and 5-wheel models adapt to different conductor diameters and stringing conditions.

Flexible Suspension Options:

Available in hook or joint plate style for quick attachment to cross arms or anchors.

Corrosion & Weather Resistant:

Engineered for outdoor use, resistant to UV, moisture, and oxidation, suitable for harsh environments.

Labor & Time Saving:

Reduces physical strain during cable laying and enhances overall work efficiency.

Technical Parameters

| Model | Sheave Type | Material | Rated Load | Cable Diameter Range | Pendant Type |

| SB-1 | Single Sheave | Aluminum + MC Nylon | 10 kN | ≤ 25 mm | Hook / Joint Plate |

| SB-3 | Three Sheaves | Aluminum + MC Nylon | 15 kN | ≤ 35 mm | Hook / Joint Plate |

| SB-5 | Five Sheaves | Aluminum + MC Nylon | 20 kN | ≤ 45 mm | Hook / Joint Plate |

(Custom sizes available upon request.)

Application Scenarios

Power Transmission Line Construction

Guiding conductors during long-distance stringing operations.

Communication Line Installation

Protecting fiber optic cables from bending or wear.

Electrical Maintenance & Retrofitting

Assisting in safe lifting and re-routing of existing cables.

Industrial and Utility Projects

Used in factories, substations, and cable trench installations.

Structure & Material Details

Sheave Material: MC Nylon with high wear resistance and self-lubricating properties.

Frame: Precision-molded aluminum alloy body ensures stability under heavy stress.

Bearing: High-precision sealed bearing for silent and smooth rotation.

Finish: Anti-oxidation surface treatment enhances longevity and outdoor durability.

Attachment: Compatible with hooks, shackles, or joint plates for easy assembly.

Each component is meticulously engineered to ensure the pulley’s long-term reliability and consistent performance across diverse industrial conditions.

Quality Control & Standards

Manufactured under ISO 9001:2015 certified quality system.

Each unit undergoes load testing, dimensional inspection, and rotational balance verification.

Complies with international safety standards for overhead line equipment.

Continuous R&D improvements ensure compatibility with modern conductor types such as ACSR and OPGW cables.

This commitment to precision and quality ensures dependable performance in every field application.

Why Choose Us

Over 15 years of manufacturing expertise in power line stringing tools.

Customizable design options to suit your specific cable type or load requirement.

Prompt global delivery and after-sales technical support.

Competitive factory pricing without compromising product reliability.

Trusted by utilities, EPC contractors, and electrical equipment distributors worldwide.

Partnering with us means choosing proven performance, engineering precision, and long-term reliability.

FAQ

Q1: Can this Stringing Block handle both aluminum and fiber optic cables?

Yes. The MC nylon sheave is gentle enough for fiber optic cables while strong enough for aluminum or steel conductors.

Q2: Are custom sizes or load ratings available?

Absolutely. We can manufacture stringing blocks based on your conductor diameter, weight, and stringing environment.

Q3: What’s the maximum load capacity?

Our standard models support from 10 kN to 20 kN, with heavy-duty versions available upon request.

Q4: How should I maintain the pulley?

Regularly check the bearings and ensure the sheave rotates freely. Apply light lubricant periodically for optimal performance.

Q5: What is the typical lead time?

For standard models, 7–15 days after order confirmation. Custom designs may require additional production time.