Portable earthing kits provide a critical safety barrier in live-line maintenance by creating a controlled, low-resistance path to ground. Without them, workers face risks from induced voltages, accidental re-energisation, or residual charge buildup. For procurement managers, contractors, or linemen in the field, knowing exactly what these kits are, how they are built, and how to select the right specification is essential. At JITAI, we supply a wide range of earthing wire set solutions and portable earthing kits designed to meet international standards and ensure maximum safety during electrical maintenance tasks.

What is a portable earthing kit?

A portable earthing kit is a safety assembly designed to temporarily connect de-energised electrical equipment or lines to the ground, providing protection for personnel working nearby. Unlike permanent grounding systems, these kits are mobile, lightweight, and intended for field use during inspection, repair, or construction.

It is important to distinguish between earthing and short-circuiting in this context. Earthing provides a discharge path for induced or stray voltages, while short-circuiting ensures that any accidental re-energisation is quickly neutralised by safely diverting fault currents to ground. Both functions are crucial to protect workers on overhead distribution lines, substations, and temporary work areas.

Typical use cases include:

Overhead transmission and distribution lines where maintenance requires a confirmed safe work zone.

Substation equipment during inspection or repair when certain sections must be isolated.

Temporary electrical works such as new installations or emergency shutdowns.

The safety goal is simple: a properly installed kit ensures that even in the event of unexpected energy appearing on the line, workers remain insulated from electric shock hazards.

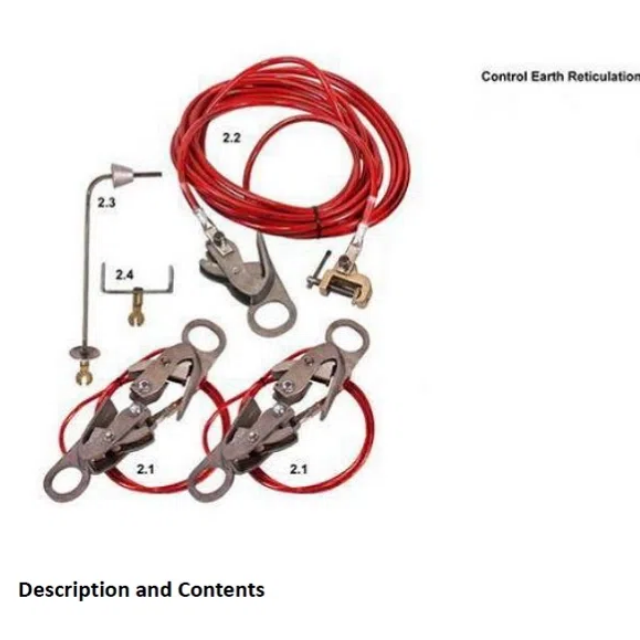

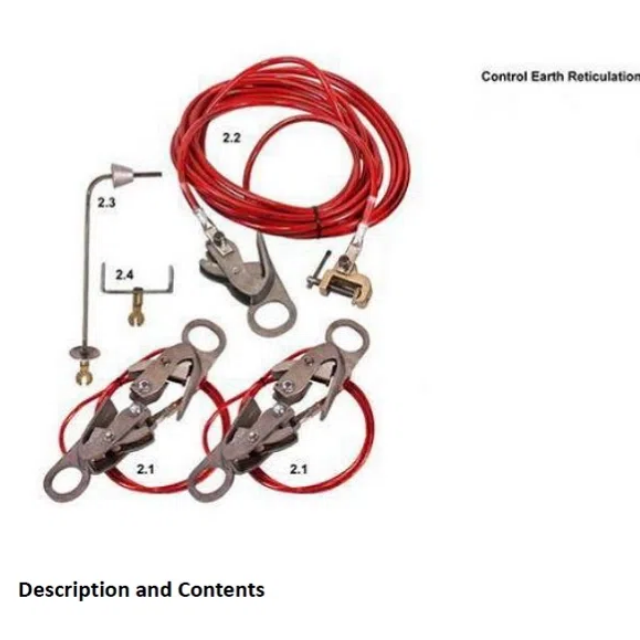

Key components explained

When sourcing portable earthing kits, it is important to understand the main components inside. Each part is designed with a specific protective function.

Insulated operating rod

Often referred to as a hot stick or operating rod, this insulated pole allows workers to connect clamps to live conductors while maintaining safe clearance. Depending on voltage levels, rods may be extendable and designed to handle specific insulation ratings.

Cable clamps and grounding clamp

The clamps form the secure mechanical and electrical connection between the conductor, the junction, and the earth point. Common materials include aluminum alloy or bronze, offering durability and conductivity. Clamps must be compatible with the diameter and surface condition of the conductors being worked on.

Junction clamp and copper grounding line

The junction clamp connects multiple cables into one point before leading into the grounding conductor. The grounding line is typically made of flexible, multi-strand copper cable designed to carry high fault currents with low resistance. Insulation sheathing enhances safety and durability.

Carrying case and accessories

Most kits come in a protective case for ease of transport. Accessories may include insulating sticks, trifurcating plates for multiple connections, and sometimes protective sleeves for conductors. Compatibility with personal protective equipment (PPE) is another critical consideration, ensuring workers can install and remove components while wearing gloves and protective gear.

Understanding these components helps buyers evaluate product quality and suitability for specific field conditions.

Ratings, standards and why they matter

Not all portable earthing kits are equal. Safety performance depends on rigorous testing, appropriate ratings, and compliance with international standards.

Short-circuit rating

A typical rating is expressed in kiloamperes (kA) for a given time, such as 20 kA for 1 second. This specifies the maximum current the kit can safely conduct to earth without damage. Selecting a kit below the required rating can lead to catastrophic failure in fault conditions.

Standards and certifications

When comparing suppliers, ensure that kits comply with relevant standards such as IEC 61230 for portable equipment for earthing or short-circuiting. Certification and test reports provide assurance of quality and traceability. At JITAI, all portable earthing kits undergo strict inspection with advanced testing equipment to confirm they meet these criteria.

Why testing and traceability matter

Manufacturers conduct high-current testing under controlled conditions to verify that cables, clamps, and junctions perform as expected. Traceability—knowing the test certificate corresponds to your actual purchase—is equally important for compliance and audit requirements.

By paying close attention to ratings and certifications, buyers can ensure that safety equipment will perform reliably when needed most.

Buying checklist — choose the right kit for your task

Selecting the right portable earthing kit requires aligning specifications with your operational environment. A practical checklist for procurement managers and contractors includes:

Match the kA rating to network fault levels: Assess the maximum prospective fault current of your system and ensure the kit’s rating is adequate or higher.

Check cable length and conductor type: Longer cables may be needed for overhead line applications, while compact cables suit substations. Ensure adequate cross-sectional area for current carrying capacity.

Clamp compatibility: Confirm that clamps match conductor diameters, shapes, and available fixed earthing points. Using the wrong clamp can compromise contact quality.

Portability and storage: For crews that move between multiple sites, a lightweight carrying case improves handling. Kits should also be easy to maintain and inspect after use.

Maintenance considerations: Look for products with replaceable parts, corrosion-resistant materials, and clear inspection guidelines to extend service life.

Following this checklist ensures that procurement decisions are based on technical fit, not just cost, reducing risks for teams in the field.

Common pitfalls and FAQs for buyers

Even experienced buyers sometimes overlook key points when selecting portable earthing kits.

Confusing electrical grounding kits with consumer wellness products: Some online searches return “grounding” kits meant for personal use in wellness markets. These are unrelated and not suitable for electrical maintenance. Always ensure you are sourcing industrial-grade equipment.

Over-specifying vs under-specifying: It can be tempting to buy the highest-rated kit available, but this adds unnecessary cost and bulk if your system’s fault levels are moderate. Conversely, under-specifying creates a safety hazard. Strike the right balance by assessing your actual network requirements.

Maintenance and inspection frequency: Portable earthing kits are not “fit-and-forget.” They should be inspected regularly for wear on clamps, cable damage, and insulation integrity. Some companies set mandatory inspection intervals aligned with safety audits.

These FAQs highlight the importance of informed procurement and ongoing asset management.

Conclusion

Portable earthing kits are indispensable for ensuring safety in electrical maintenance, providing workers with a trusted path to ground and protection against unexpected energy. By understanding their components, ratings, and selection criteria, procurement managers and contractors can make informed choices that balance safety and practicality. At JITAI, we supply high-quality portable earthing kits and earthing wire set solutions backed by strict testing and quality management systems. To learn more, request a datasheet, ask for a kA test certificate, or contact us directly for a tailored quote. Contact us today to discuss your project needs and ensure your crews are equipped with reliable safety tools.